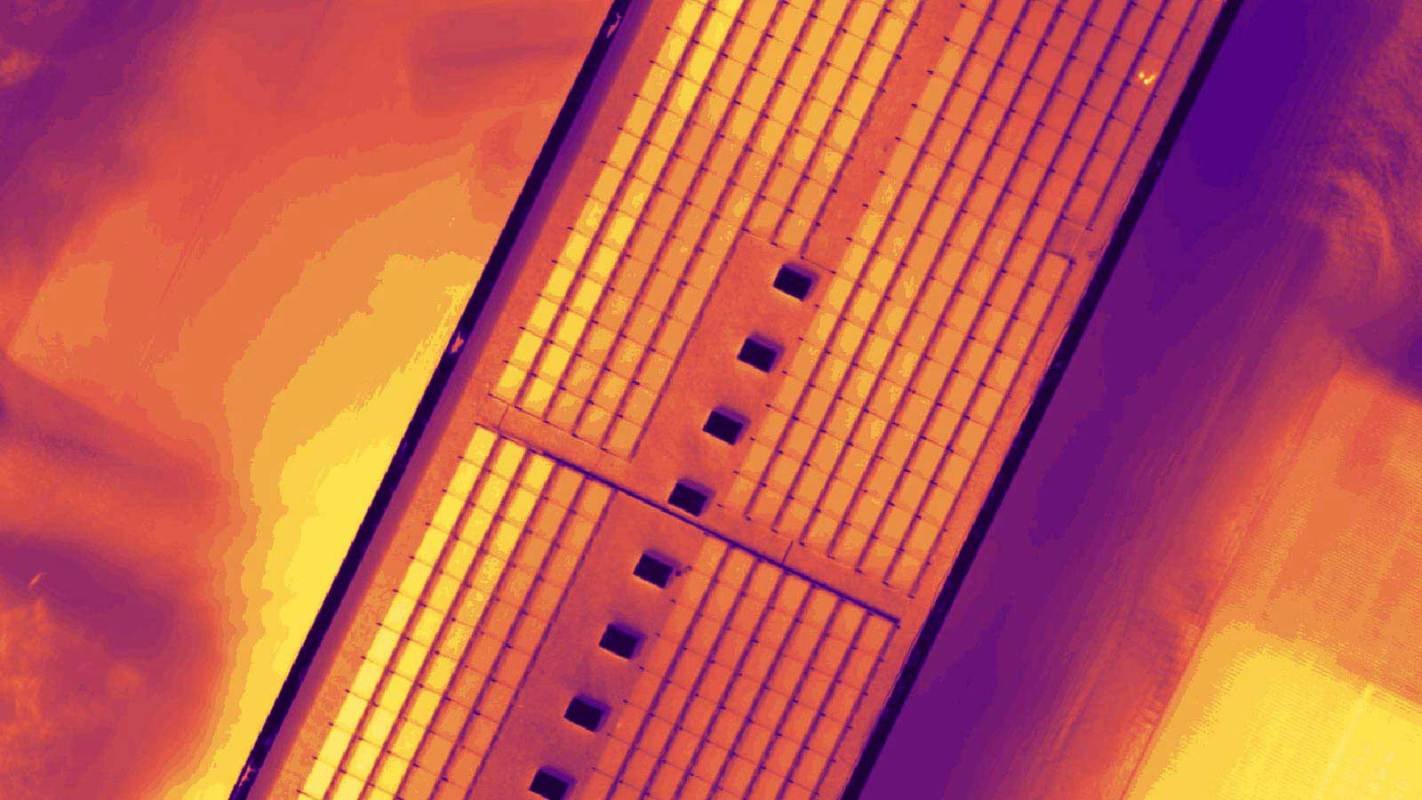

Thermographic Inspection

Since 2015, Above has been at the forefront of developing innovative technology to help its customers build and sustain longer-lasting, higher-performing solar plants.

A market leader in drone inspections for solar, Above pioneered their use, setting industry standards for precision and reliability.

Our software platform, SolarGain, provides unparalleled insights into solar plant health, ensuring compliance with IEC standards for EPC and O&M contracts, technical due diligence, and warranty claim processes.

Understand the health of your solar asset.

Regular thermographic inspections with Above allow you to build a reliable performance dataset, enabling detailed analysis and comparison across your solar portfolio over the module's lifetime.

We can offer IEC standards and best practice guidelines, ensuring consistent, high-quality data collection across all your solar sites worldwide.

Benefits of Above's Thermographic Inspection

Establish a Comprehensive Baseline

Regular thermographic inspections with Above allow you to build a reliable performance baseline, enabling detailed analysis and comparison across your solar portfolio over the asset’s lifetime.

Global Standardisation

Our aerial imagery adheres to IEC standards and best practice guidelines, ensuring consistent, high-quality data collection across all your solar sites worldwide

Support for Warranty and Insurance Claims

Create a robust digital thread of historical data to track module failure rates over time. Access to high-quality, standardised data enhances the likelihood of successful warranty and insurance claims.

Advanced Power Loss Modelling

Developed in collaboration with the academic experts at Loughborough University C.R.E.S.T, our industry-leading power loss model evaluates the impact of thermal anomalies in the context of your electrical system design, providing precise insights into performance losses.

Targeted Maintenance Planning

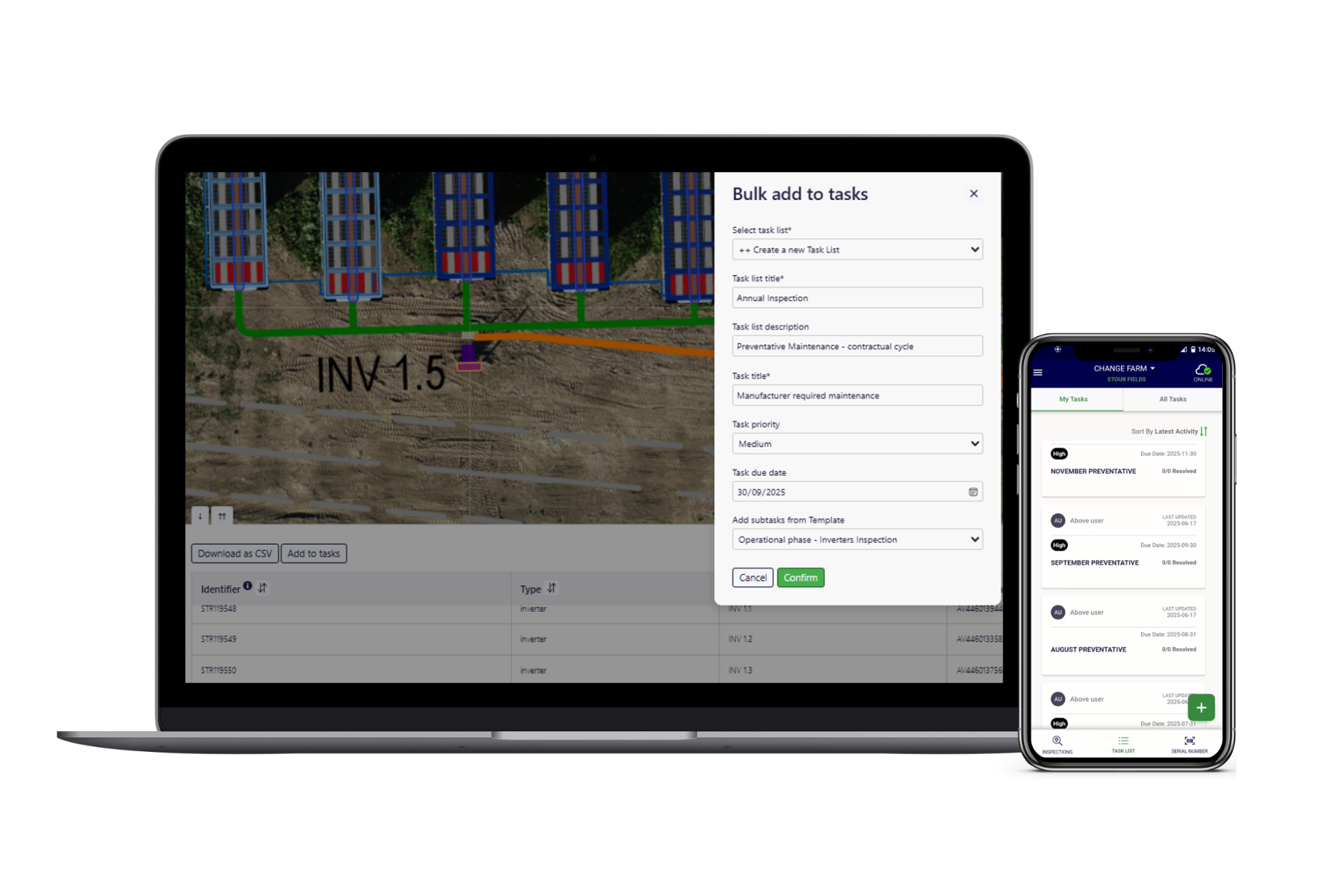

Streamline your operations by quickly identifying specific issues and using the Task List feature to efficiently direct resources to where they are needed most.

Mapped and Integrated Data

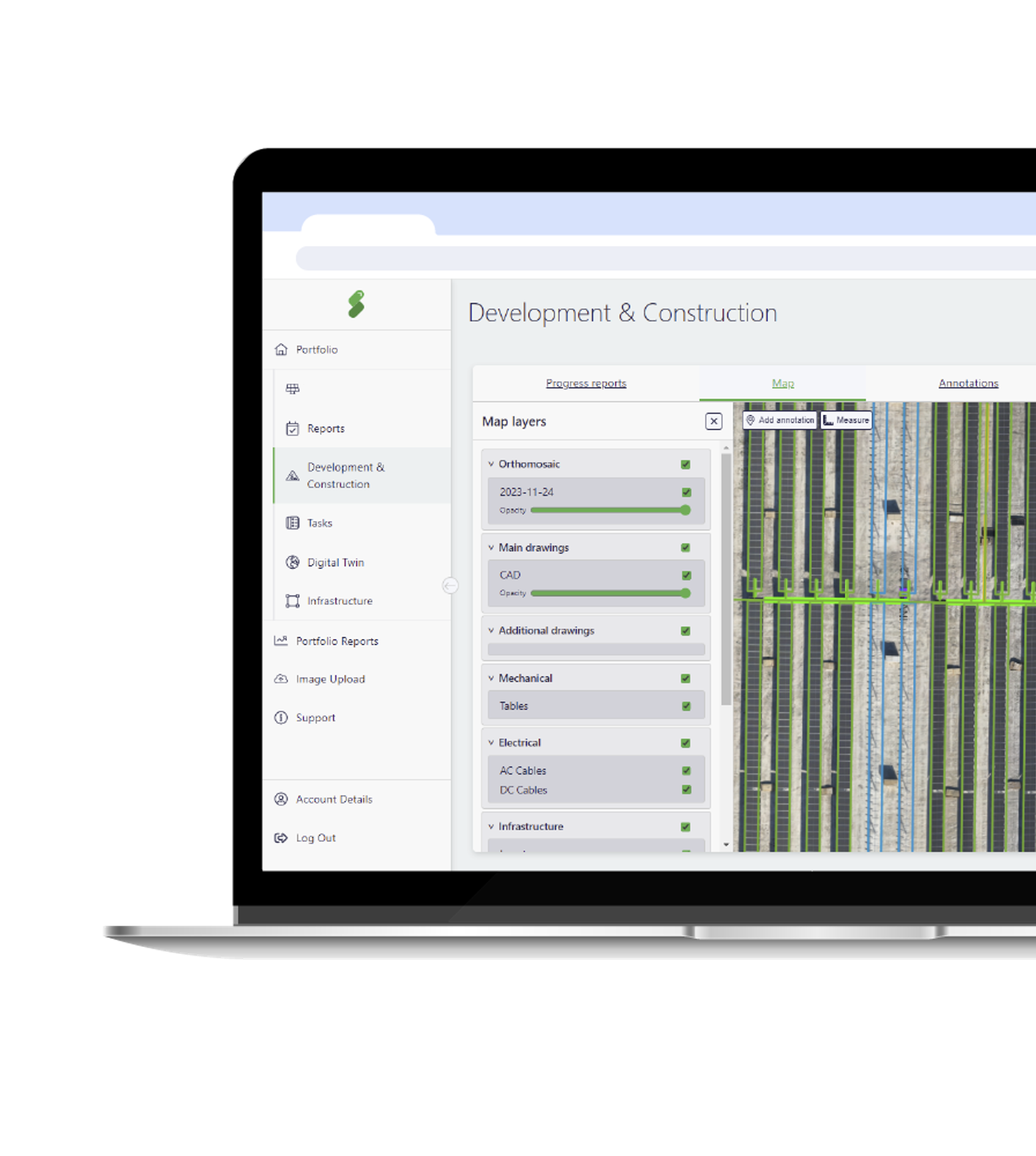

Inspection data is electrically and spatially mapped to precise module locations within SolarGain, Above’s powerful cloud-based platform.

Download the Thermographic Inspection Checklist today.

Introducing SolarGain

SolarGain delivers forensic inspection data in digestible form, providing deep insights into the health of your solar plant. By identifying, assessing, and addressing potential performance issues using thermographic data, SolarGain significantly speeds up root cause diagnosis, prioritisation and efficient human intervention.

Why use Thermographic Inspections?

Whether you are commissioning or buying a new plant, performing general health checks or making a warranty or insurance claim, our solution ensures you understand the detailed health and performance of your solar plant.

With global coverage and the option for clients to self-fly their data collection, our approach is both scalable and adaptable to your needs. Above’s aerial inspections are also supported by our suite of mobile apps, giving you instant access to geolocated data, performance analytics, and actionable task lists and reports on site and in physical and electrical context.

FAQs

-

A thermographic inspection is a type of infrared thermal imaging assessment that uses specialised cameras to detect heat patterns and temperature differences across the surface of objects. In the solar industry, this technique identifies thermal anomalies in photovoltaic modules or solar plant infrastructure without physical contact.

-

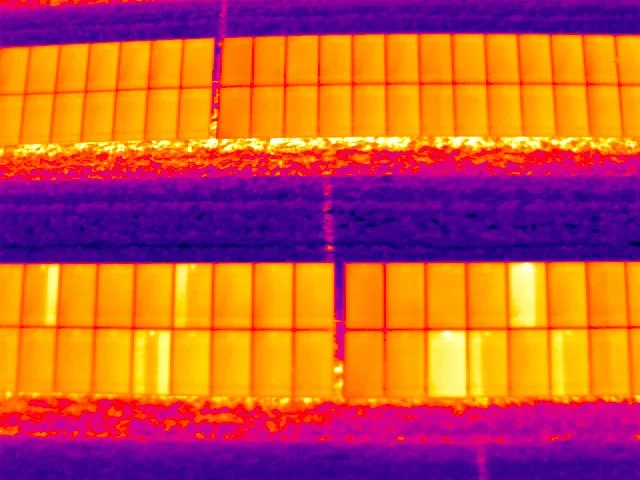

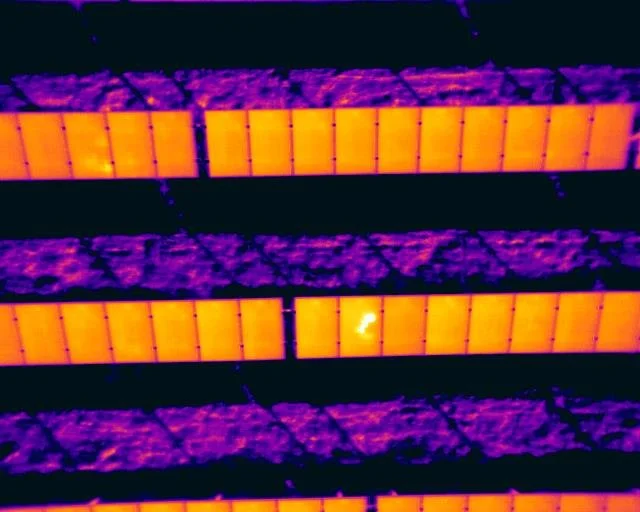

Above uses drone-based infrared cameras to capture high-resolution thermal imagery across solar assets. These thermograms reveal hotspots or performance issues, which are then analysed through Above’s SolarGain platform giving operators precise, geolocated performance data and actionable insights.

-

Thermographic inspections help solar asset owners:

Detect electrical and thermal anomalies early

Improve preventative maintenance and reduce downtime

Support commissioning and warranty claims

Build a long-term performance baseline

Improve yield forecasting and operational decisions

These benefits stem from revealing issues invisible to the naked eye and traditional inspections.

-

Thermal imaging can uncover issues such as hotspots, string imbalances, junction box overheating, shading losses, and other electrical or thermal irregularities that could impact plant performance or component lifespan.

-

Yes. Thermographic inspection is a non-destructive, non-contact testing (NDT) method that doesn’t require de-energising equipment or physically touching components, making it safe and efficient for large-scale solar operations.

-

Yes. Above provides global thermographic inspection services, giving solar O&M teams, EPCs, and asset owners consistent, high-quality thermal data across international sites.

-

After the inspection, clients receive detailed thermal reports with:

Thermographic imagery and heat maps

Identified anomalies and their locations

Performance analytics

Contextual insights for maintenance or claims purposes

These results are integrated into the SolarGain platform for easy access and decision-making.

-

Generally, a site representative is not required onsite during the drone thermographic mission; however, it’s important to provide access details, safety instructions, and any site access information needed for the flight.

-

The recommended frequency varies by asset age, operations schedule, and performance goals. Traditionally, annual or bi-annual inspections align with maintenance windows, though many operators choose more frequent monitoring to track performance trends over time.

-

Yes. High-quality, IEC-standard compliant thermographic data enhances the likelihood of successful warranty and insurance claims by providing standardized, robust evidence of module faults or degradation.

-

Before inspection, sites should ensure cleanliness (e.g., panel washing) and clear access for drone operation. Above may coordinate with clients on scheduling, weather conditions, and site access protocols to ensure optimal data capture.

-

Thermal images (thermograms) convert infrared signals into colour-coded temperature maps. These visuals help technician’s pinpoint anomalies, understand their severity, and plan corrective action, all accessible via SolarGain’s dashboards and reporting tools.

-

Stakeholders that benefit include:

O&M teams looking to improve uptime and efficiency

EPCs verifying construction quality

Asset owners tracking long-term performance

Warranty administrators and claims specialists

These groups use thermographic insights to make data-driven decisions.

Be part of the solar plant revolution.

See SolarGain in action, Our team is happy to help!