Bifacial PV Modules - A comprehensive guide

25/10/2023

Are you planning a solar plant and contemplating using bifacial PV modules? Would they boost electrical output and yields? What challenges would they pose compared with other modules? In this blog post, we will explain what differentiates bifacial modules from traditional panel designs. We will discuss the pros and cons, and key factors for yield calculations and maintenance.

What makes bifacial PV modules different?

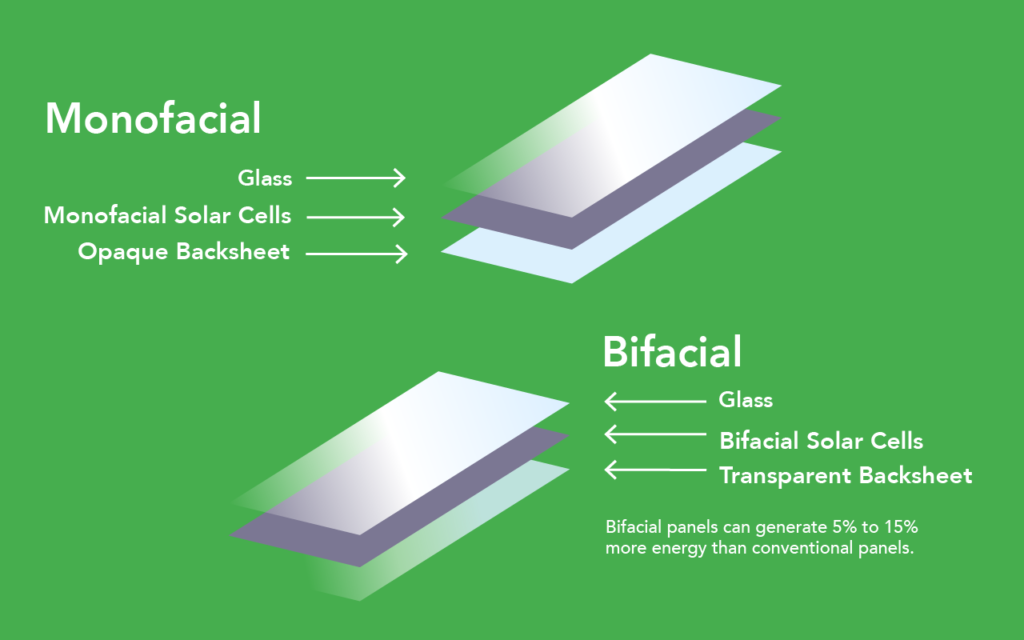

While bifacial PV modules aren’t a new invention, they are relatively new to utility-scale solar arrays. It is projected that bifacial installations will constitute up to 40% of new deployments by 2025. So let’s look at how they differ from other modules. Bifacial PV panels differ from conventional monofacial panels in their design and operational principles. Traditional PV modules are monofacial, meaning they only absorb sunlight on the front surface of the solar panel. Monofacial modules use opaque back sheets while bifacial modules often incorporate transparent or translucent back sheets or dual-glass designs.

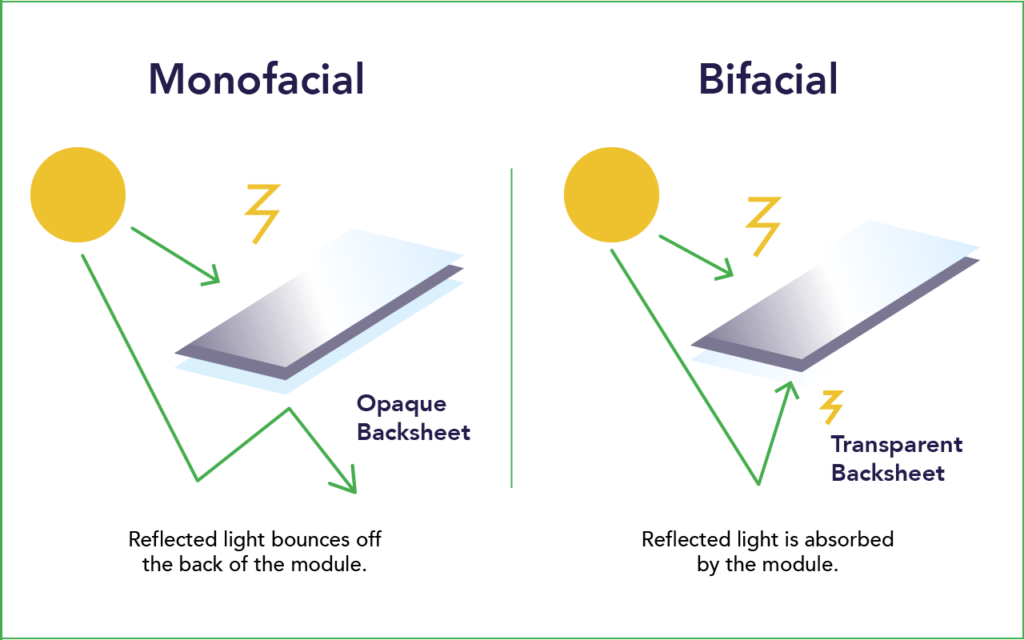

Because they capture sunlight on both sides, bifacial modules can generate more power (and better yields) in smaller arrays. Even higher yields are possible if they are installed on a highly reflective surface (more on this later). Because bifacial solar panels harness energy from both sides they require unique glass types for each side. The front glass is typically thicker, designed for durability and UV resistance while the rear glass is generally thinner. That’s because it is tailored for optimal light transmittance to capture refracted sunlight efficiently. Installing bifacial panels on an elevated mounting system helps to maximize the amount of reflected light they can capture.

There are also differences when it comes to the DC junction boxes, where the PV strings are electrically connected. Both monofacial and bifacial panels feature a DC junction box on their rear, housing and protecting bypass diodes. However, bifacial panels need a more compact junction box design to decrease rear-side shading effects. Unfortunately, this compactness can introduce potential thermal challenges, stressing specific components or soldering points.

Diagram illustrating the differences between backsheets in monofacial and bifacial PV modules.

What problems can arise in bifacial modules?

Bifacial panels can generate 5% to 15% more energy than conventional panels. However, the dual-sided energy capture, while beneficial, introduces certain complexities. We just mentioned the DC junction box design. The increased current generation can place added stress on the cell structure, potentially leading to issues such as hotspots. Just to explain, a hotspot is an area that experiences overproportional heating than the rest of the panel. Hotspots can damage the modules and reduce their power output.

Partial shading on the panels’ rear side can also accentuate thermal stress on the cells. The dual-sided nature of bifacial panels can lead to rear-side soiling and uneven shading patterns. Equally, issues that exist with monofacial modules such as delamination, bubbles, and micro-cracks can also exist with bifacial modules.

How does albedo affect bifacial modules?

We already touched on better outputs through highly reflective surfaces. The fraction of sunlight that is reflected by the panels, the so-called albedo, is a crucial aspect for bifacial panels. That’s because the energy output of bifacial panels’ rear surface relies on irradiance reflected from the ground. The albedo or reflectivity of the ground surface, can have an impact on the panels’ electrical energy output. However, the irradiance varies, because the surface type can change considerably, depending on the location and the season. This makes it difficult to develop a model which covers all possible cases. Albedo is an important focal point for current research, such as the SYMBIOSYST Project which Above is participating in. The varied effects of albedo on bifacial panels as identified from aerial drone inspection data need to be further substantiated. Spatial and temporal albedo measurement inputs into the yield model are also of great importance.

Diagram illustrating the differences between light absorption in bifacial and monofacial PV modules.

How is thermographic inspection affected by this module type?

Bifacial modules’ unique dual-sided structure requires a new approach to thermal inspection data interpretation, particularly when using aerial drones. That’s because the bifacial design diverges significantly from traditional monofacial setups, which complicates standard thermal diagnostic techniques. Because they harness light from both sides, bifacial panels exhibit unique thermal behaviours compared to traditional monofacial panels. For example, the differential power generation across the module due to uneven rear-side irradiance can create distinct thermal signatures. In addition, thermal patterns may vary, depending on ground surface conditions (e.g., vegetation, soil, concrete). Temperature distributions can also be altered as a result of ground or structural reflections.

New module technology – new uncertainties

The rapid adoption of bifacial modules without extensive data underscores the need for a careful industry approach. While they offer efficiency gains within a smaller footprint, their construction and maintenance pose new challenges. As a result, their unique traits demand a fresh understanding from industry professionals. A vigilant approach to condition monitoring is key to accurately identifying anomalies and sustaining system efficiency.

The solar industry’s reliance on simulation models and factory degradation prediction rates has been integral in forecasting panel performance. However, there’s a clear limitation: many of these models, despite their sophistication, are built upon limited datasets. This can lead to predictions that might not wholly represent real-world operational nuances, particularly when it comes to bifacial panels.

However, these predictions potentially influence both investor decisions and the perceived long-term viability of solar plants. Addressing these challenges requires thorough benchmarking and consistent tracking of solar plants after completion. Using detailed operational data, the industry can refine its predictive models for more accurate forecasts. This approach strengthens both the dependability of future installations and stakeholder confidence in the industry’s abilities.