Understanding IEC 62446-3:2017 - Outdoor infrared thermography

01/11/2023

Do you need to source aerial thermographic inspection services for your solar PV array? Are you wondering what industry standards apply and what their requirements are? Perhaps you’ve heard of the standard IEC 62446-3:2017, but aren’t quite sure what it means in practice? In this blog post we will explain what IEC 62446-3:2017 is and what its requirements are.

What is IEC 62446-3:2017?

In previous blog posts, we talked about aerial thermographic inspections often referring to IEC 62446-3:2017 compliant inspections. However, the question is: What do we mean by IEC 62446-3:2017?

For outdoor thermography of solar PV, the IEC TS 62446-3:2017 is often cited as a key standard to meet. It is often referred to in EPC contracts, technical due diligence scope and warranty claim procedures.

In case you’re wondering, “IEC” stands for International Electrotechnical Commission. The IEC is an international standards organization that prepares and publishes international standards for all electronic, electrical, and related technologies. This also includes photovoltaic installations.

There is a wide range of equipment and approaches for thermographic inspections. These can yield an equally wide range of data. That’s why it’s important to know what you want to achieve with that data. Is your intention, for instance, to use it for technical due diligence or a warranty claim? Then you should understand the standard that should be adhered to.

IEC requirements for aerial thermography

Within the IEC 62446-3:2017 standard, the use of drones has only really been considered in the context of basic inspections. The standard refers to drones as ‘fast carriers’ for module thermography only. In other words, drones are not involved in the testing of other electrical components, such as wiring or inverters.

Aerial drones are increasingly being used as part of the tool kit for fault detection and localization in PV plants. That’s because they help scale, automate and accelerate the detection of faulty areas within solar plants. This kind of drone inspection is classified as a simplified inspection procedure of the whole PV array. Its purpose is to find PV sub areas, strings or modules with problems.

The standard also covers so-called simplified thermographic inspections with reduced requirements for the qualification of personnel. This applies to limited inspections to test the basic functioning of PV modules, for example during the commissioning of systems. These inspections can’t provide authoritative conclusions regarding the actual module quality.

Since 2017, when IEC 62446-3:2017 was first developed, there have been advances in the equipment and image processing software. These have improved effectiveness and value to the end user and increased the take up of this inspection approach. Undoubtedly, the standard will be further developed to accommodate this maturing approach to outdoor thermography.

Requirements for environmental conditions

Section 5.3 of the IEC 62446-3:2017 standard outlines the environmental conditions under which inspections should be carried out. The most important parameter in this list, which will have the greatest impact on the results, is the irradiance level. Cloud coverage impacts irradiance, but can also lead to inspections with fluctuating conditions for both thermal and RGB imagery. Just to explain, RGB cameras take coloured images by capturing light in red, green, and blue wavelengths (RGB). Whereas infrared sensors work by detecting infrared radiation, which is emitted by all objects with a temperature above zero. Because they don’t determine absolute temperatures, they use thermal patterns to evaluate the abnormalities.

Wind speed is another important environmental factor during aerial inspections. However, as long as the drone is stable, variations in wind speed typically have a small effect on the inspection results. Last but not least, soiling can lead to many false positives. That’s why soiling and vegetation should always be removed before carrying out module thermography.

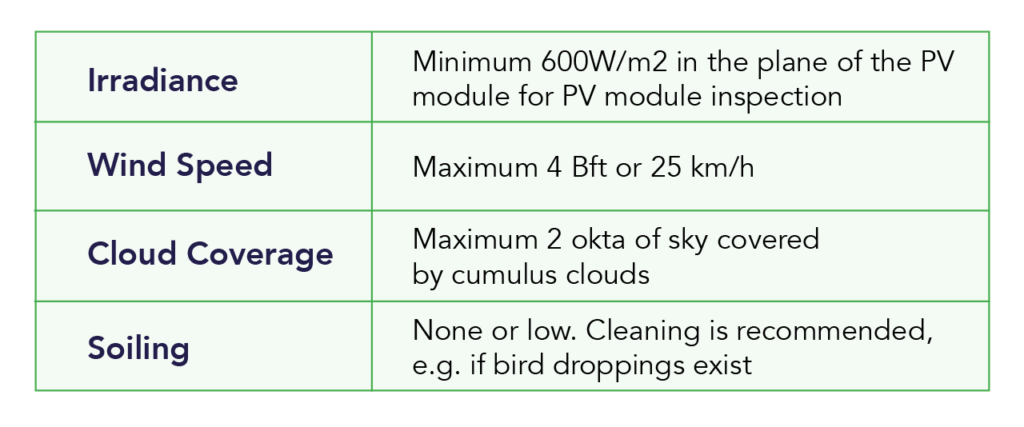

IEC 62446-3:2017 requires aerial inspections to be carried out under the following conditions:

This table shows the conditions required to carry out IEC 62446-3:2017 compliant aerial thermographic solar plant inspections.

IEC 62446-3:2017 requirements regarding geometric resolution of imagery

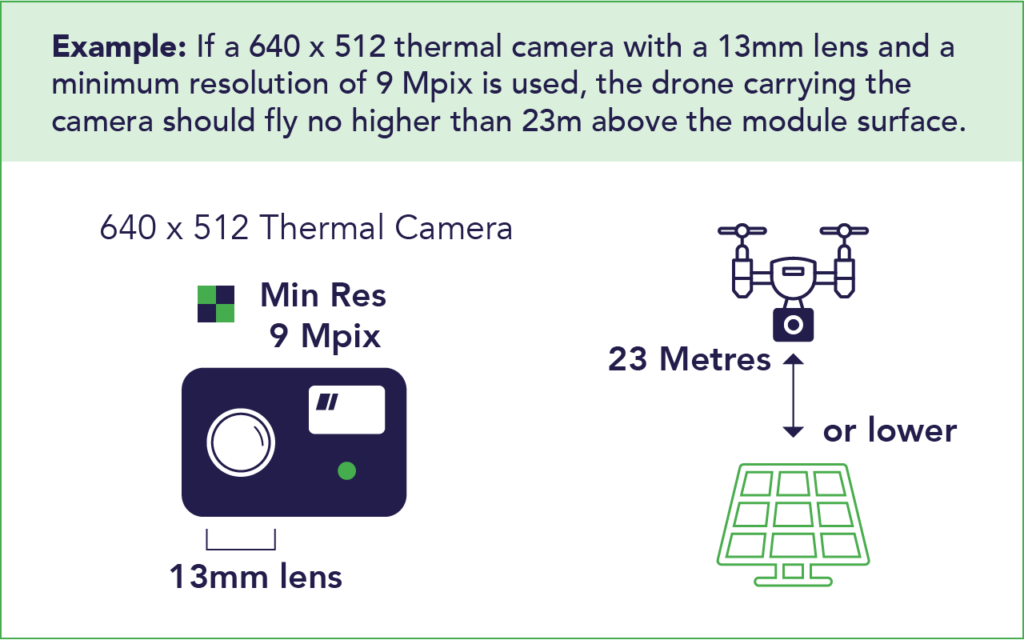

The IEC 62446-3:2017 standard also outlines the requirements for geometric resolution. This parameter has a direct bearing on the accuracy of temperature measurements generated from the inspection data. Geometric resolution is a function of the drone height above the module, the sensor angle, lens and camera resolution. All PV modules shall be recorded with a minimum resolution of 5×5 pixels per cell. Deviations from IEC 62446-3:2017 will have a direct impact on the accuracy of the inspections’ measurements. This in turn can jeopardize the credibility and quality of the inspection data.

This image shows an example of the height needed to perform an IEC-compliant thermographic inspection of a solar PV plant when using a specific 640 x 512 camera.

Aerial thermography – a useful tool for module condition monitoring

Used correctly, drones meet and even surpass the definition of the ‘Simplified inspection’ within the IEC standard. High-quality aerial thermography and analysis can provide credible and valuable module condition data down to the cell level. But, just like ground-based thermography, aerial thermography alone cannot always provide a conclusive diagnosis of identified faults. As a result, other ground-based measurements may be required to determine the impact and root cause.

Flying the drone/sensor carrier higher than the standard requires may reduce service costs, due to reduced (drone) pilot time. However, it will also limit the value of the results due to the reduced quality of data. Systemic issues, such as PID for instance, often have minimal differences in temperature gradient. Flying the sensors higher than IEC makes the difference between seeing or not seeing a suspicion of PID. Depending on module types – thin-film modules in particular -, we even recommend surpassing the IEC requirements. To get a deeper understanding of other non-drone-related methods, read this blog post on aerial thermography performed with a plane. It is important to have a clear understanding of your requirements before sourcing aerial thermographic inspection services.

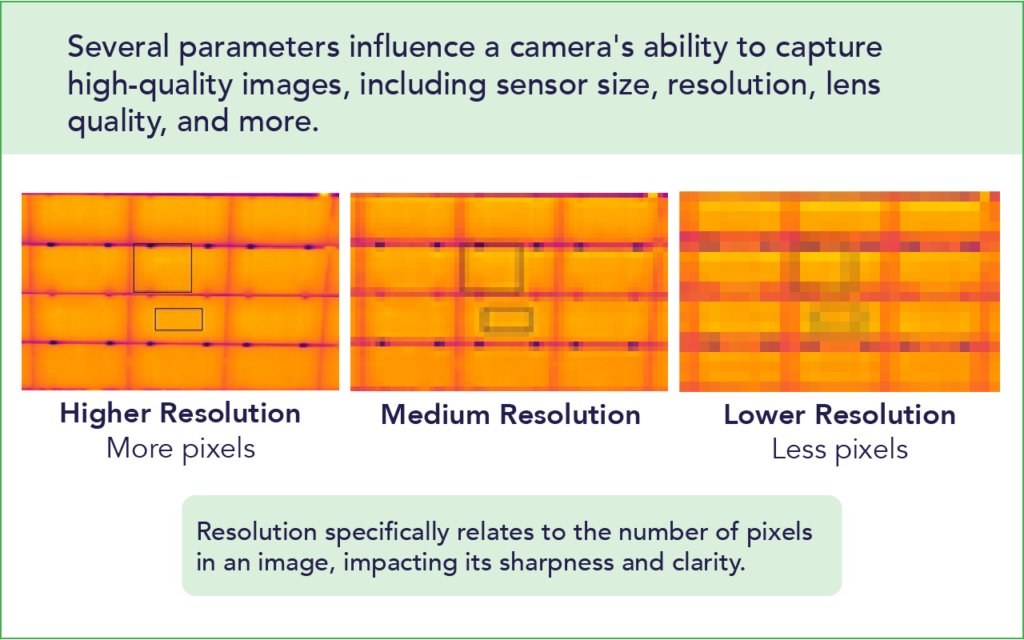

This example shows how image resolution impacts the quality and overall ability to identify subtle thermal anomalies. Resolution specifically relates to the number of pixels in an image, impacting its sharpness and clarity.