PID on PV modules - What, why and how to deal with it

18/10/2023

Are you wondering what PID on PV modules is, how it manifests itself, and how damaging it can be? Would you like to find out what methods there are to identify it and how early can it be spotted? And what should you do if PID is confirmed on your modules? Below we try to answer all these questions and help you and help decide how to proceed.

What is PID on PV modules?

Potential-induced degradation (PID) is one of the most detrimental problems for crystalline silicon and thin-film solar panels. That’s because it degrades the modules’ power output and reduces the performance ratio (PR) of solar plants. While it doesn’t initially show as performance loss, if untreated it later has a massive impact performance. Eventually, it can result in power losses of up to 40%.

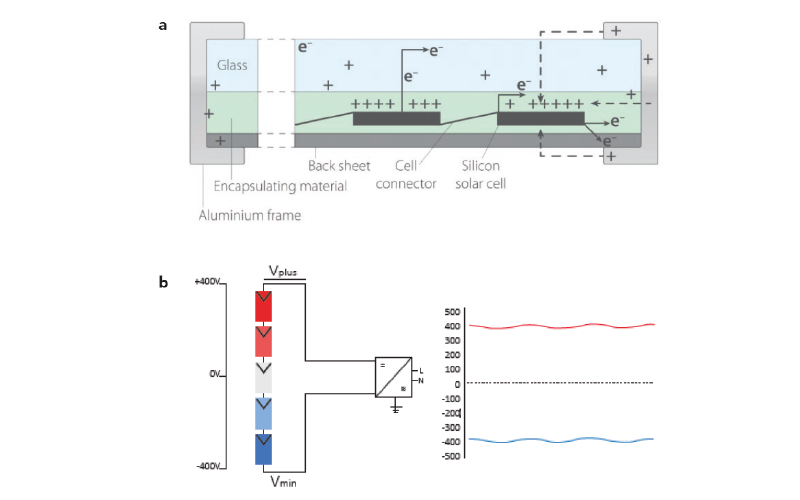

To explain in more detail what PID actually is, let’s begin by looking at the typical PV system architecture. This consists of strings of modules, connected in series to generate a high voltage. For safety reasons, the frames of the modules are grounded. This causes a potential difference between the cells and the outer part of the modules. The potential difference can lead to a leakage current between the modules’ silicon semiconductor and other module materials. When this happens, the resulting potential-induced degradation causes the modules’ temperature to rise rapidly. Unless it’s stopped, this leads to the failure of the entire PV system, resulting in performance and yield loss. The likelihood for PID is exacerbated by the higher voltage strings that are now being used across the industry.

So far, no predictive models have been developed for PID. But we know what factors can influence whether PID will occur. At the module level, these include the encapsulation material, anti-reflective coating on cells, and the structural design of the modules. At the system level, while the frames of the modules are grounded, inverters generally don’t provide a functional ground. As a result, a high potential difference between the modules’ cells and the frames is left floating. This initiates the PID-related degradation at mostly the negative end of the string, though it may also appear on the positive end.

Graphic illustration of Potential Induced Degradation (PID) on PV modules.

Can you see PID in thermographic inspection?

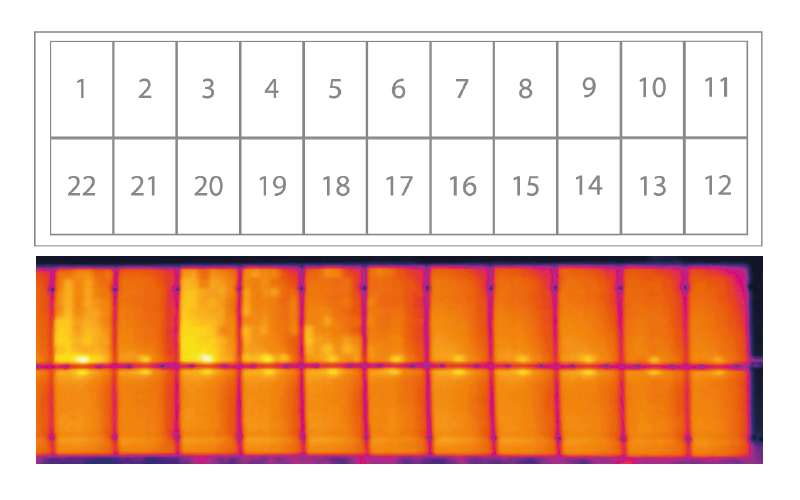

Because PID typically progresses uniformly, there’s often limited differential on the strings that would raise an alarm before yield loss occurs. Because yield loss may only become apparent after many years, it’s important to identify PID early on. The most effective way to spot PID is an IEC 62446-3 compliant aerial thermographic inspection. In thermography, sensors detect infrared radiation, which is emitted by all objects with a temperature above zero. Because a module’s radiation increases with temperature, the PID-induced temperature increases become visible to a thermographic camera. Affected cells are considerably hotter than surrounding cells, and are usually located at the negative end of a string. This so-called ‘string-end heating pattern’ (SEHP) can be a sign of PID – but it doesn’t have to be.

Thermal inspection imagery of a 22-module string from an aerial thermographic inspection by Above – Modules 1, 3, 4, 5 and 6 exhibit multiple cells which are considerably hotter (more yellow) than other cells/modules and the affected modules are located at the end of a string. This so-called ‘string-end heating pattern’ (SEHP) is highly suggestive of PID.

How to determine that SEHP is PID?

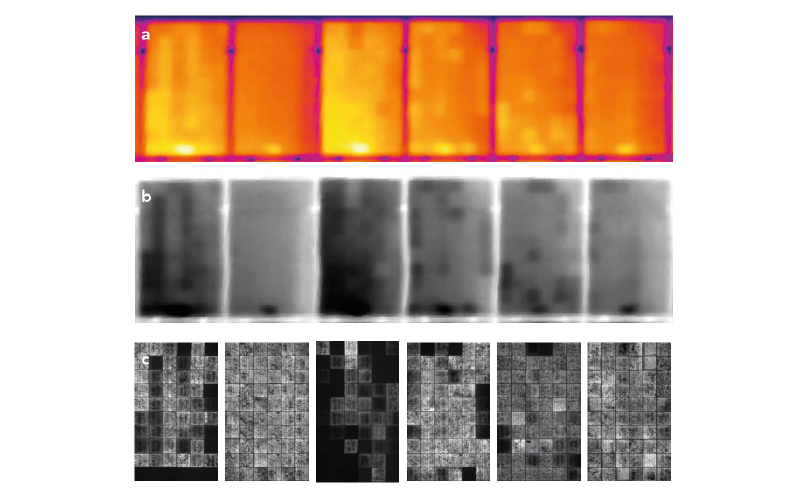

Because PID is a systemic issue on solar sites, when it does appear it shows with frequency and consistency. If that isn’t the case, the identified SEHP may point to other issues that need investigating. It’s important not to classify an anomaly as PID because you cannot be certain with aerial thermography alone. Having said that, thermography can identify with very high certainty that there is an anomaly that requires further investigation. Further ground-based testing will help to validate and confirm whether the modules are affected by PID. Established methods for this are Electroluminescence (EL) and current-voltage (I-V) curve measurements. Just to explain, EL refers to the light emitted by a material in response to an electric current. And I-V is a standard test to measure a module’s current-voltage characteristic.

PID is a systemic issue on solar modules that progresses slowly. This means that the earlier you identify it, the more success you will have in recovering the situation.

A comparison between different inspections of PID-affected PV modules. a, thermographic imagery (more yellow denotes hotter cells). b, thermographic imagery ( darker colour denotes hotter cells) and c, Electroluminescence images (darker colour denotes degraded/ deactivated cell).

What to do when inspections have confirmed PID on your PV modules?

Thankfully, PV modules with PID can be recovered. The success of the recovery process depends on, e.g., the module type, degradation depth, and the local humidity and temperature. There is no one-size-fits-all solution, only individual solutions for each array.

One solution is to fit the array with so-called reversal boxes, also known as charge equalizers. The idea is to reverse the effects of PID over time and prevent it from continuing. This is done by putting a DC current through the module at night to reverse the PID. However, this solution isn’t 100% perfect, and not all modules will recover.

Alternatively, float controllers can be added to change the potential. These can be retrospectively fitted to a system to prevent further PID onset. Any recovery through these measures will usually be evident within a few months. In this case, the reversal boxes stay on the array to reverse out the PID as it propagates. If the reversal doesn’t work, the next step is to submit a whole batch replacement warranty claim.

How to start a warranty claim in case of PID?

Having said that, solar PV modules typically have a 10-year product warranty which covers product failure. After 10 years, you may be looking at a performance warranty. This, however, requires evidence that the module has declined in performance compared with what is expected after 10 years. Unfortunately, most in-field performance testing tools have a tolerance that is outside of what is required for successful warranty claims. Having data to provide evidence of degradation over time makes warranty claims more robust. (This is where benchmarking and condition monitoring comes in. We discussed this in earlier blog posts.) And being able to refine a serial anomaly to a specific module batch may add more weight to your warranty claim.

If you would like to know more on this topic download our whitepaper ‘Determining PID using aerial thermography’.