Are you an owner of a large solar asset or an engineering, procurement, and construction contractor (EPC) working on solar projects? Do you find it increasingly difficult to keep track of all the tasks that have yet to be completed? Do you wish for a better way to keep control of subcontractor’s work? Are you overwhelmed by the sheer challenge of inspecting large solar installations? Do you wish there was an easy way of building and managing your construction punch list? In this blog post, we will discuss how digitalization and the resulting tools can make your life easier, reassure your investors and keep all stakeholders in the loop.

What is a construction punch list?

For those of you who are not working with construction punch lists daily, let us look at what they are. Construction Punch Lists are nothing new – they’ve been used for centuries in different forms. First on pen and paper, later in Excel spreadsheets. They’re basically a list used by architects, engineers, and project managers to track any work that must be carried out before a construction project is completed.

Speaking specifically about solar construction, construction punch lists used to be moving targets, with items constantly being added chronologically. The means to add items to a punch list was through visual inspections carried out on foot. Both missing technological capability as well as human error often led to a lack in evidence being collected. This made it difficult to oversee which inspections and electrical or mechanical tests had been carried out. Let alone understanding their results and implications.

While solar projects were small, it was mostly possible to keep an overview despite the above-described challenges. However, as plant sizes are scaling up and becoming more complex, so are their construction punch lists. Depending on the region plant sizes range from 10+ MW to hundreds or in some cases even gigawatt plant sizes. With solar installations increasing in size like this, it’s becoming ever more difficult to track tasks and their resolution.

What does digitalization bring to construction punch lists?

While maintaining good construction punch lists has been a challenge, technological innovation and digitalization are now acting as game-changers. Overall, digital construction punch lists are part of a wider move towards software for better solar construction management. Thankfully, software and digitalization improve efficiency (how to collect data and store it), quality (detail and smartness of data being stored), and power (both in an electrical sense as well as a personal sense).

Technology advances have made it possible to create a digital representation of an installation, often referred to as digital twin. If done correctly, a digital twin understands your solar site on a geospatial, an electrical and a component level. This means that (almost every) component is accessible as an individual item against which information can be stored. It also understands the electrical layout of the site, making it possible to look at isolated electrical areas such as strings, inverters, or transformers.

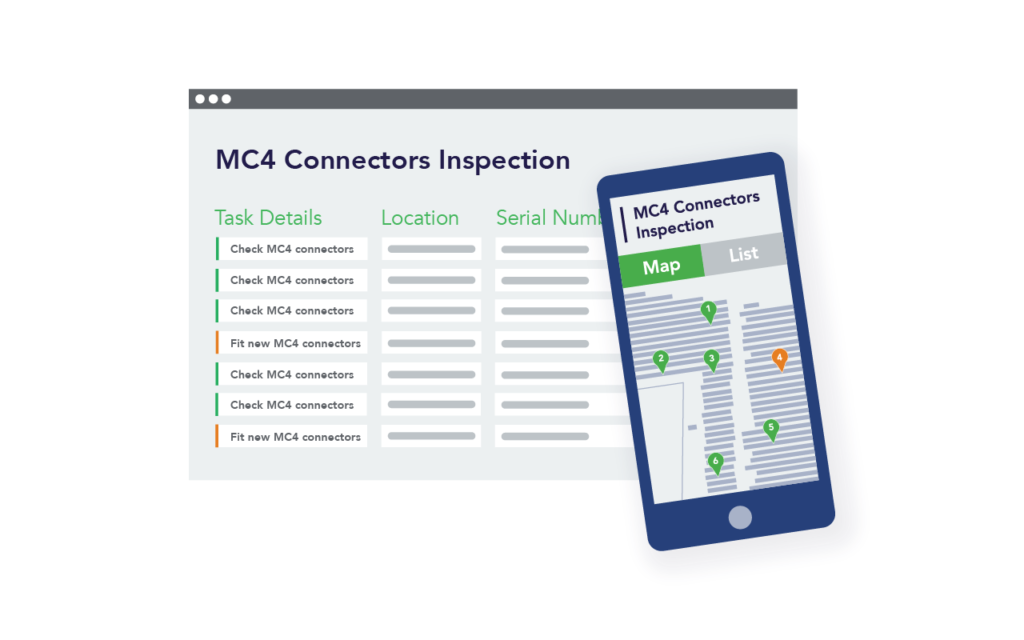

How does this influence construction punch lists? Using the digital twin as the basis, a digital construction punch list can store information at a component level. While performing a visual inspection, an engineer can add items directly to a component using a mobile application. The possibility to immediately evidence and attribute any issue onsite improves efficiency tremendously. Additionally, when a new item is added, there is a well-structured task history and visual evidence tracking exactly what work was carried out where, when and by whom. Bringing all this data together on one platform reduces time and costs. Furthermore, it also increases quality because more detail is stored in a smart way. Here “smart” refers to the capability of the software to understand and hence support your analysis activities through filter and search functions.

Improving power through digital construction punch lists

As explained above, digital construction punch lists improve efficiency and quality. But how do they improve power, you might ask? Very simple: By improving transparency and data accessibility. With the right software, all information collected can be made available to relevant stakeholders from one single data set. Gone are the days of lengthy discussions, arguments, or even legal litigation when word stands against word. Everyone who has been involved in building a solar site has plenty of such stories to tell.

Besides personal evidencing power, employing a digital twin software makes it possible to also connect other test and inspection data. Examples are for instance geolocated images generated from drone-based construction monitoring or thermographic inspections performed at grid connection. This way, issues can be identified early and be mitigated leading to less delays to the date of grid connection.

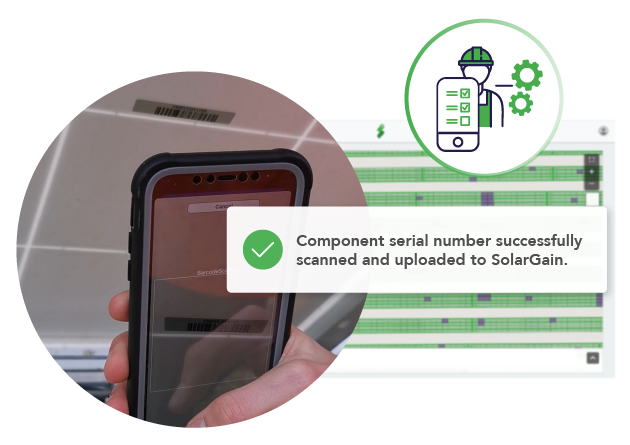

Combining this with collecting serial numbers, this is a great start into detailed condition monitoring thereby increasing decision power. High quality digital twin technology allows users to track modules from factory to field. Punch list items can then inform the O&M teams about potential issues influencing future purchasing decisions. Ultimately, the quality of the construction is going to translate into the quality of the operation.

How do stakeholders benefit?

While digitalization of construction punch lists supports efficiency of EPC, it also benefits other stakeholders. Combining data collected during routine aerial and “boots on the ground” inspections in one platform means information is readily available. Giving data a structure in a digital twin, ensures the pipeline ahead operates more seamlessly, and reduces risk and liability. As a result, investors can feel reassured that the necessary due diligence has been verifiably carried out. This in turn secures their return on invest over the duration of the plant’s operational lifecycle. Additionally, if investors want to divest, they own a robust dataset to demonstrate the quality of the plant.

Furthermore, works completion punch list can help achieve regulatory compliance by efficiently organising the data required for testing and inspection. Creating a digital construction punch list can improve transparency and accountability. Together with well-defined contractual obligations, this ensures the asset meets the minimum standards required.

Digital construction management software is becoming a standard

Spreadsheets may still be the industry standard in solar construction, but the move towards digital construction management solutions including construction punch lists is quick. The benefits are too manifold, and a lot of value is lost by not having data at a component level. Additionally, as mentioned before, project complexity is too much to handle manually. As a result, the industry is maturing and moving towards digital tools and mobile apps.

The unprecedented levels of scrutiny offered by this technology may be new to EPCs. However, the data generated by these tools protects them from claims and liability for damages. These tools enable EPCs to meet their deadlines while having visual evidence at their disposal to demonstrate contractual compliance. They may also enable them to differentiate themselves on the basis of the quality of their data, and be more competitive by having more efficient works completion.

If you are interested in understanding the history of solar construction and the role innovation plays in this area, we recommend watching this pv magazine webinar on Smarter utility-scale solar construction with digital tools.