Independent Engineering Professionals

Assurance built on evidence

Above provides Independent Engineers with a complete suite of digital assurance, construction management, and thermographic inspection tools designed to verify solar project quality from factory to field.

Our SolarGain Software delivers data-driven visibility, enabling engineers to monitor progress, validate workmanship, and confirm that every component meets technical and warranty requirements.

Download the Digital Construction Management Brochure today.

Frustrations that we help you solve

Manual, time-consuming reporting

Automated analytics and standardised templates streamline reporting, turning complex site data into ready-to-share documentation.

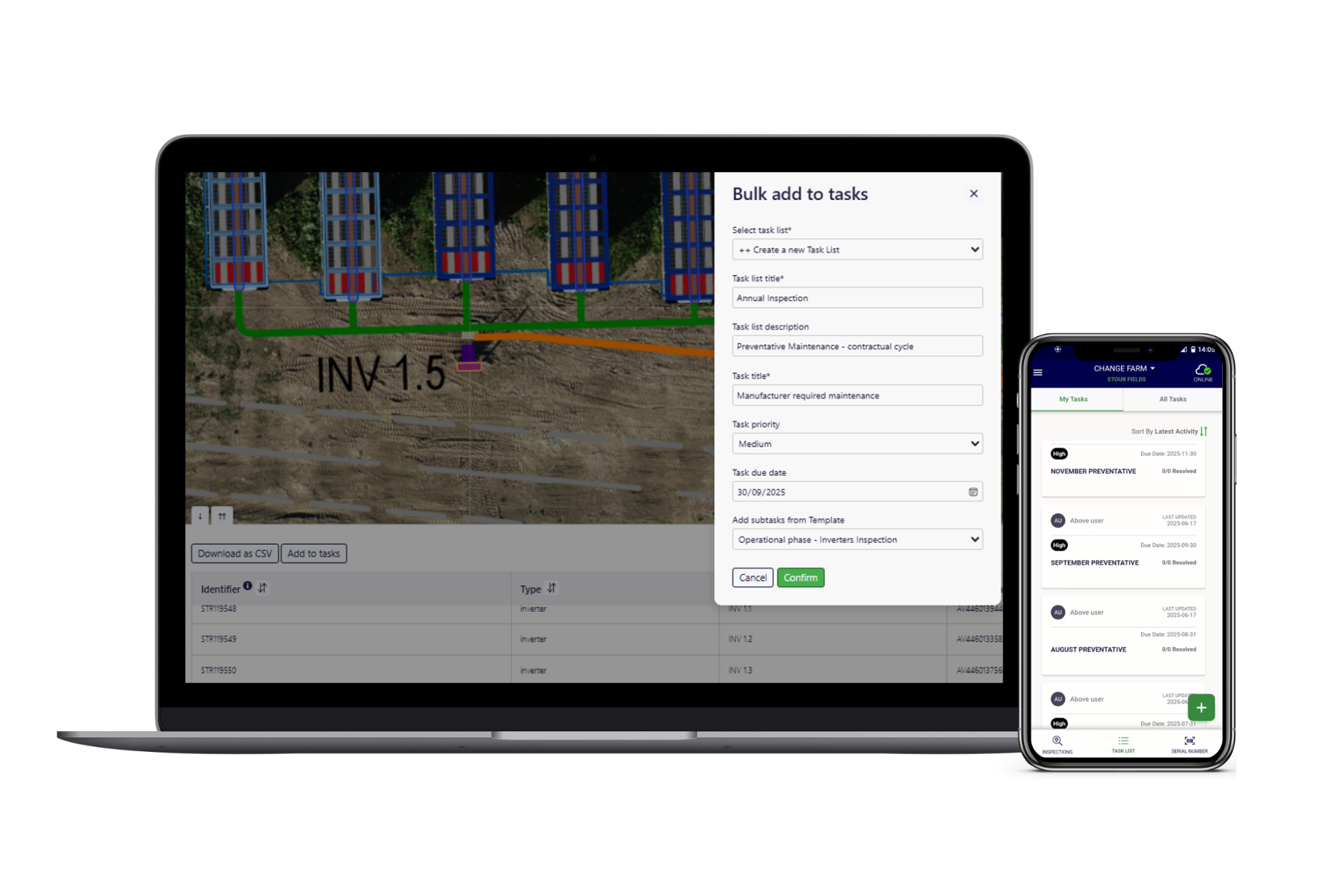

Above’s mobile inspection tools sync directly with the Digital Twin, capturing issues, images, and punch-list actions in real time.

Inefficient site inspection processes

Inconsistent or incomplete project data

Above provides a single, digital source of truth combining aerial imagery, thermography, and QA records into one verifiable platform.

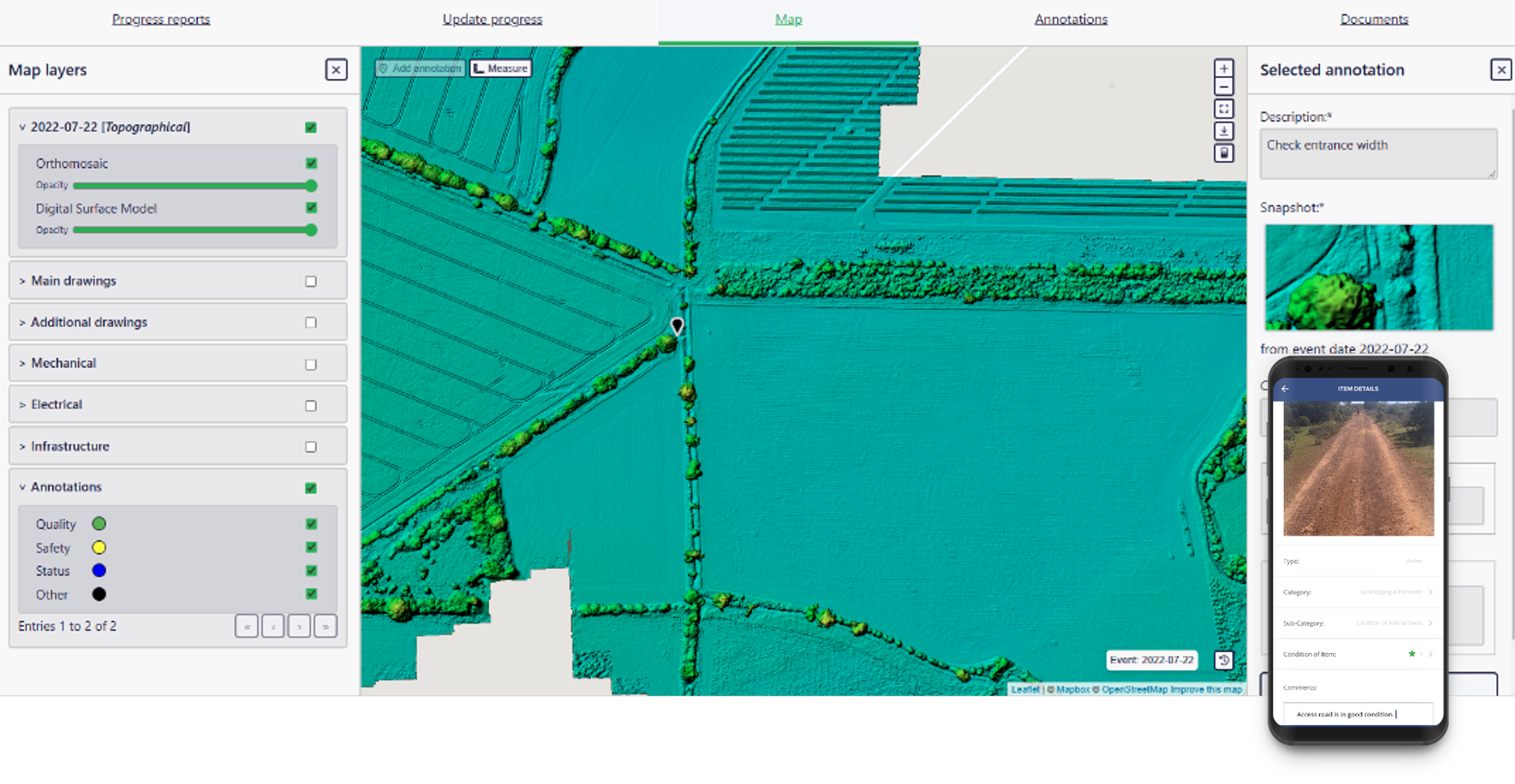

Limited construction visibility

The Digital Construction Management dashboard delivers live, geolocated progress updates so engineers can track every zone remotely.

Aerial thermographic surveys provide independent, site-wide performance validation, ensuring every acceptance test is backed by evidence.

Limited data for commissioning and handover

All data is standardised across projects and regions, giving IEPs a consistent QA/QC framework for global oversight.

Maintaining QA consistency across portfolios

HOW.

Above helps engineers verify with quality

Through Above’s Digital Construction Management and Digital Twin platforms, Independant Engineering Professionals can:

Track module quality from manufacturing to installation with serial-number traceability.

Monitor construction progress using aerial imagery.

Record on-site inspections, raise non-conformities, and manage punch lists via Above’s mobile app.

Conduct independent commissioning validation with full-site thermographic scans.

Create consistent, verifiable reports for milestone approvals and performance guarantees.

All data is timestamped, geolocated, and standardised, forming a single source of truth for every project phase.

Our impact in numbers

Up to 60% faster project validation. Reduce manual QA and reporting time through automated analytics, digital evidence capture, and geolocated milestone verification

40% fewer site visits are required with aerial thermography and construction tracking dashboards, allowing engineers to identify issues early and reserve site visits for high-priority inspections.

75% improvement in data consistency. Standardise QA/QC documentation across projects and contractors through Above’s connected digital ecosystem

WHERE.

Where digital assurance adds value

Independent Engineers can access Above’s digital ecosystem anywhere, from office to field:

Factory to Field QA: Link manufacturer and pre-shipment test data with site performance.

On-Site Inspections: Use mobile apps to log, verify, and track punch-list items.

Construction Oversight: View real-time progress and quality insights through the DCM dashboard.

Commissioning & Reporting: Validate system performance and generate audit-ready documentation.

Whether overseeing global portfolios or a single site, IEPs gain the independent, digital assurance needed to deliver confident sign-off and investor-grade reporting.

FAQs

-

Above’s Module Quality Assurance process tracks every module from factory to field, linking manufacturer test data, pre-shipment test results, post-shipment test results, along with installation and thermographic results for full traceability.

-

Above’s Digital Construction Management platform uses aerial imagery and thermography to show real-time build progress, helping engineers verify workmanship and milestone completion without being on-site.

-

Aerial thermography from Above scans every module to detect performance issues, providing timestamped, geolocated evidence for PAC/FAC documentation and warranty validation.

-

Above’s mobile inspection app makes fieldwork faster and more accurate by syncing visual observations, defects, and punch-list actions directly to the Digital Twin.

-

By combining drone imagery, construction analytics, and QA records in one platform, Above enables IEPs to independently verify EPC performance against specifications and schedule.

-

Above centralises all inspection data, imagery, and analytics into a single reporting framework, ensuring consistency and compliance across different regions and project partners.

Solar plant phases

Construction

Operation

Development

Be part of the solar plant revolution.

See SolarGain in action, Our team is happy to help!