Operations

When construction ends, the priority shifts to reliable generation at the lowest operational cost. O&M teams run lean, budgets are tight, and every intervention must count. Above Surveying provides precise data and insights to help operations teams identify issues early, optimise maintenance, and maximise asset performance, keeping operations efficient, safe, and cost-effective.

The Day to day reality

Small issues like soiling, string faults, or module degradation quietly chip away at yield. Manual inspections across vast, remote sites are slow and costly. And while data exists, it’s often scattered, slowing down decisions, reporting, and results.

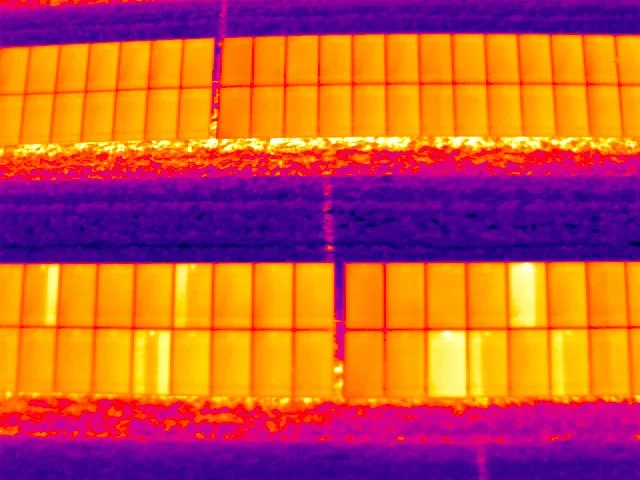

Aerial Thermographic Inspections

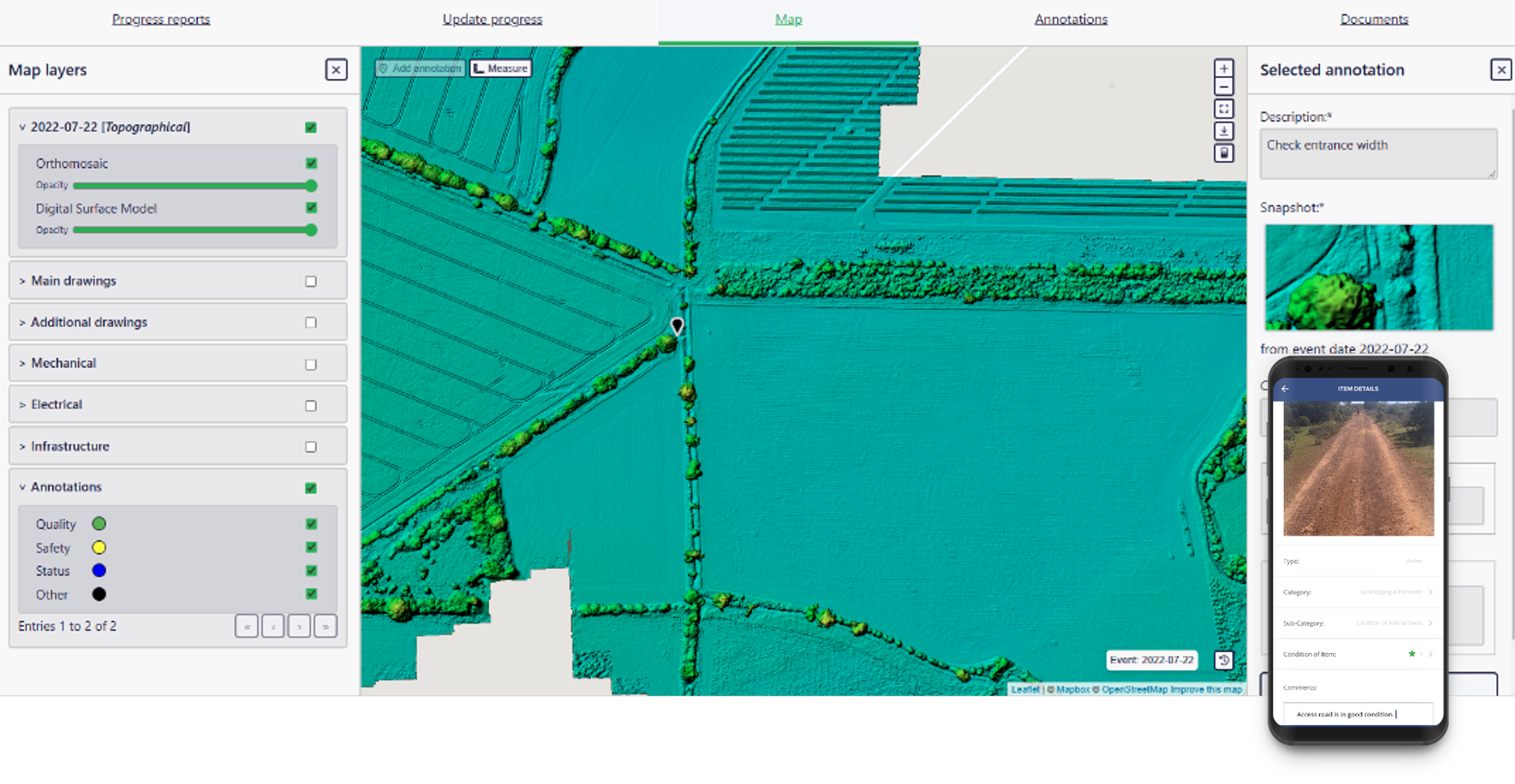

Regular aerial surveys feed into a live digital twin of your operational site.

A single, visual source of truth. Spot issues early, and maximise yield potential.

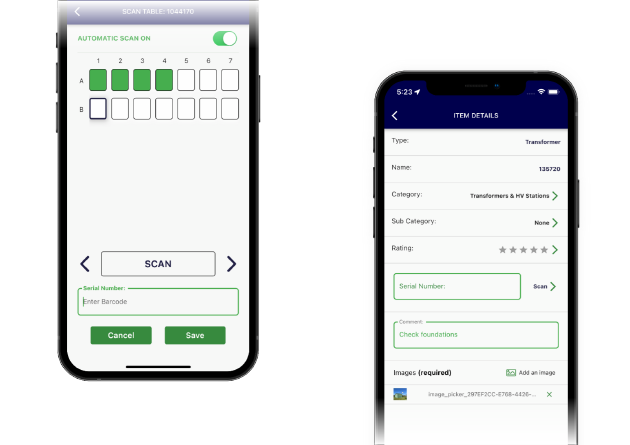

With SolarGain Mobile, site teams record what’s happening on the ground. Photos, notes, updates all geo-tagged and synced to the digital twin. It connects the field and the office, speeding up decisions and keeping everyone aligned.

Frustrations that we help you solve

Loss of information from site

Above’s mobile tools sync updates instantly, keeping everyone aligned and informed in real time.

Above pinpoints faults automatically with geo-located and geo-referenced data, so your team can focus on fixing the issues.

Too much time finding issues

Maintenance without direction

Above’s analytics prioritise high-impact tasks, guiding preventive work that protects yield.

Hidden links between faults and performance

Above’s digital twin connects inspection data and analytics, showing exactly how issues affect output.

Above unifies aerial, field, and performance data into one visual platform for total clarity.

Disconnected data sources

Above’s aerial intelligence and dashboards visualise underperformance clearly, turning complex data into action.

Hard to measure performance loss

Getting the mix right - Corrective vs Preventative

Corrective work fixes failure after the fact (downtime, higher cost). Preventive work, guided by real data, keeps output up and truck-rolls down.

Goal: spend less time everywhere and more time exactly where it matters. Pinpoint underperformance, quantify impact, and prioritise preventive tasks over costly corrective visits with SolarGain.

See the whole asset, not just the symptoms

Unify inspections, analytics, and component history in a single, visual platform. Plan routes, brief teams, and track issues from identification to resolution, all with full context and historical insight. Streamline operations, improve accountability, and keep your projects on schedule.

Find issues at scale

Thermal and RGB drone flights quickly capture detailed data across the entire site, mapping hotspots, shading, and vegetation patterns in a matter of hours instead of days, providing teams with fast, actionable insights to inform maintenance, planning, and operational decisions.

Aerial Thermography Inspection

From office to site (and back again)

Great insights only help if field teams act fast and efficiently.

Technicians receive geo-precise tasks, capture photos/notes, work offline, and sync instantly, with less admin, faster closes, and better evidence.

FAQs

-

Above identifies underperformance across modules and strings using aerial thermography and analytics, helping you target the issues that have the biggest impact on generation.

-

It combines inspection data with performance analytics to prioritise maintenance, showing you where to focus your time for the highest yield return.

-

It delivers clear, geo-precise tasks and allows technicians to work offline, capture photos and notes, and sync automatically, ensuring every fix is verified and traceable.

-

The Digital Twin connects your inspections, analytics, and site records into a single visual source of truth, helping you plan, track, and report efficiently.

-

Most operators run annual flights, though higher-frequency monitoring is valuable in challenging environments or under performance guarantees.

-

Yes. By guiding teams to the most impactful interventions, Above reduces truck rolls, unnecessary site visits, and reactive maintenance.

-

Yes. Above can ingest SCADA data via partnerships to enhance performance analytics with real-time operational context.

-

All actions, inspections, and verifications are captured digitally, creating a traceable evidence base that supports transparent reporting and investor confidence.

See how it works

See SolarGain in action, Our team is happy to help!