If you’re in the solar PV industry, you’re familiar with solar tracker systems. If not, read our introductory blog post on choosing a solar tracker system. In this post, we’ll explain why you should be monitoring solar tracker systems from construction and what tools to use.

![]()

Monitoring solar tracker systems: Why does it matter?

Investing in a solar tracker system is a smart choice that yields returns when properly maintained. Faulty trackers can disrupt power generation, highlighting the importance of monitoring their condition.

By conducting regular maintenance, solar plant managers can ensure that solar panels operate at peak efficiency, optimising energy output and enhancing overall performance. This not only maximises the financial returns on the investment but also extends the lifespan of solar equipment, reducing the need for premature replacements and lowering long-term operational costs.

How to start monitoring solar tracker systems from construction

For monitoring the mechanics and control of solar PV trackers during operation, standalone systems typically feature integrated control software, ensuring reliable communication and prompt alarm response with SCADA. SCADA systems effectively read data and transmit commands to tracker controllers.

In the next section, we explore how digital tools support the visual monitoring of solar plant trackers from construction.

Insights for monitoring solar tracker systems from the sky

Aerial data is a powerful way of monitoring the tracker installation progress. With bird’s eye views, solar teams gain crucial insights into the progress of tasks such as trench digging, piling and module mounting. This allows for comparison with the solar plant design, flagging and resolving any deviations that occur. Aerial construction monitoring enables efficient tracking and control of construction quality that is often impossible to spot from the ground.

![]()

Utilising mobile tools for ground-based monitoring of solar tracker systems

Ground-level monitoring of solar tracker systems is equally essential for ensuring efficient operations. With the SolarGain Mobile app, construction teams can enrich, track, and control the quality of construction directly from the ground. Keeping a digital record of correctly installed tracker mechanisms and structures can save time and money for possible unexpected warranty claims. Using a mobile app automates data recording, ensuring accuracy and efficiency compared to managing vast, disconnected spreadsheets or no data at all.

Scanning your components’ serial numbers helps to allocate a component to a specific batch. It also enables you to keep up with maintenance. All mobile data is uploaded to exact locations on a map of the site so you can easily compare it with your aerial data. Get up to speed with the power of using mobile apps for solar activities in our mobile applications for the solar industry post.![]()

The right software for the construction management of solar tracker systems

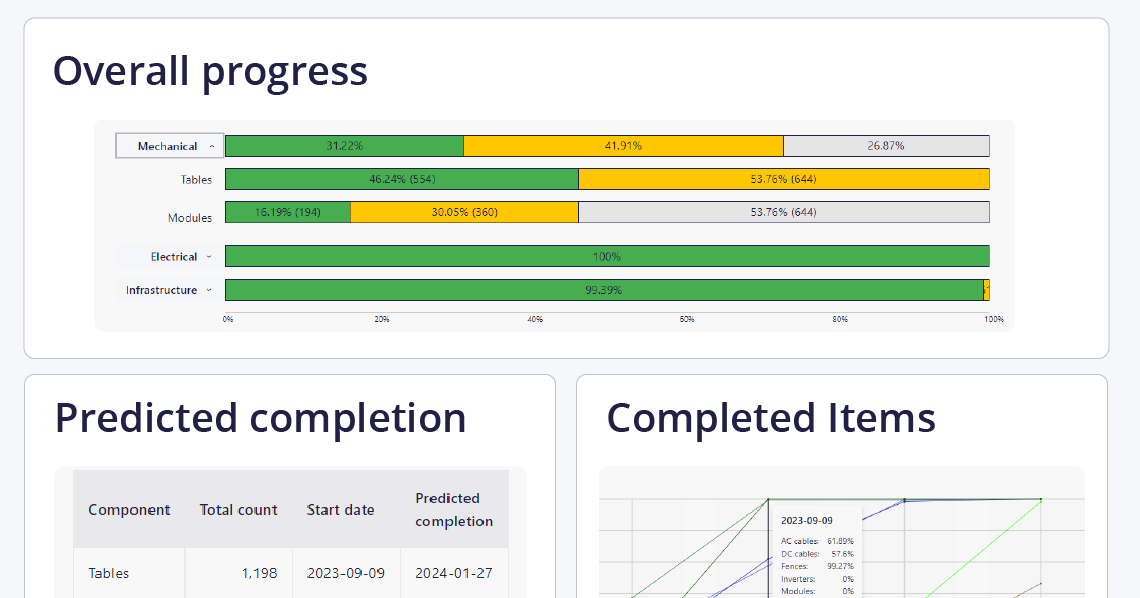

Incorporating software solutions into the construction management process further enhances the efficiency and effectiveness of managing solar tracker system installs. Digital construction management platforms allow for the seamless transition from construction to operational life by creating a comprehensive digital plant record. Additionally, with all construction management data consolidated in one place, it enhances transparency and ease of management if the project is sold.

Aerial thermographic inspections of tracker systems

Tracker alignment and mechanism faults that impact panel orientation can significantly decrease performance. On large solar plants, it can be difficult to notice these issues when on site. That’s where aerial thermographic inspections come in. They are intended to capture thermal module anomalies, but they also identify non-thermal issues, such as tracker faults and misalignment. They can help you spot if modules have gone missing, e.g. after strong winds.

Shadows on the PV modules can cause a loss of generation, all trackers now have a backtracking algorithm. That’s a tracking control program that helps to reduce any shadow one row of trackers may cast over another. This presents as an anomaly on the bottom part of the modules during thermographic inspections.

There was a time when trackers had to be paused for aerial thermography inspections. Thankfully it is no longer necessary to stop trackers from operating during aerial thermographic inspections. That’s because it is possible to adapt to the tracking angle of any specific section at the time of the inspection. Consequently, there is no loss of performance (and no loss of income) because of an inspection.

Got a project in mind?

Solar plant construction needs a 360-degree view, what you can’t see from the ground, you can see from the air and vice versa! We hope this blog post gives you some insights into monitoring solar tracker systems at construction and how to safeguard one of your most valuable components when operational.