Discover how to reduce technical debt in solar PV using digital tools. Frustrated by your installation’s sudden degradation? Are technical faults seemingly occurring out of the blue? Wondering whether your purchasing decisions were right or doubting the quality of your modules? Could costly repairs and reworking have been avoided? Below we’ll be looking at how to reduce or avoid technical debt in solar assets with the help of digital tools.

What is technical debt, and why are we talking about it?

You’re probably wondering what technical debt means. The term originated in the software industry, to describe the consequences of prioritising quick development and functionality over long-term maintainability and quality. For example, technical debt in solar may refer to issues resulting from poor procurement, design, or construction decisions that lead to higher operational costs and decreased efficiency over the asset lifespan.

In the solar industry, technical debt describes the accumulation of issues resulting from poor procurement, manufacture, design, or construction. As a result, high operational overheads and associated costs accrue later in the asset lifecycle. For example, the equipment may require costly repairs later, or its maintenance may require high numbers of staff. These costs can derail yield forecasts and revenue projections regarding long-term asset performance.

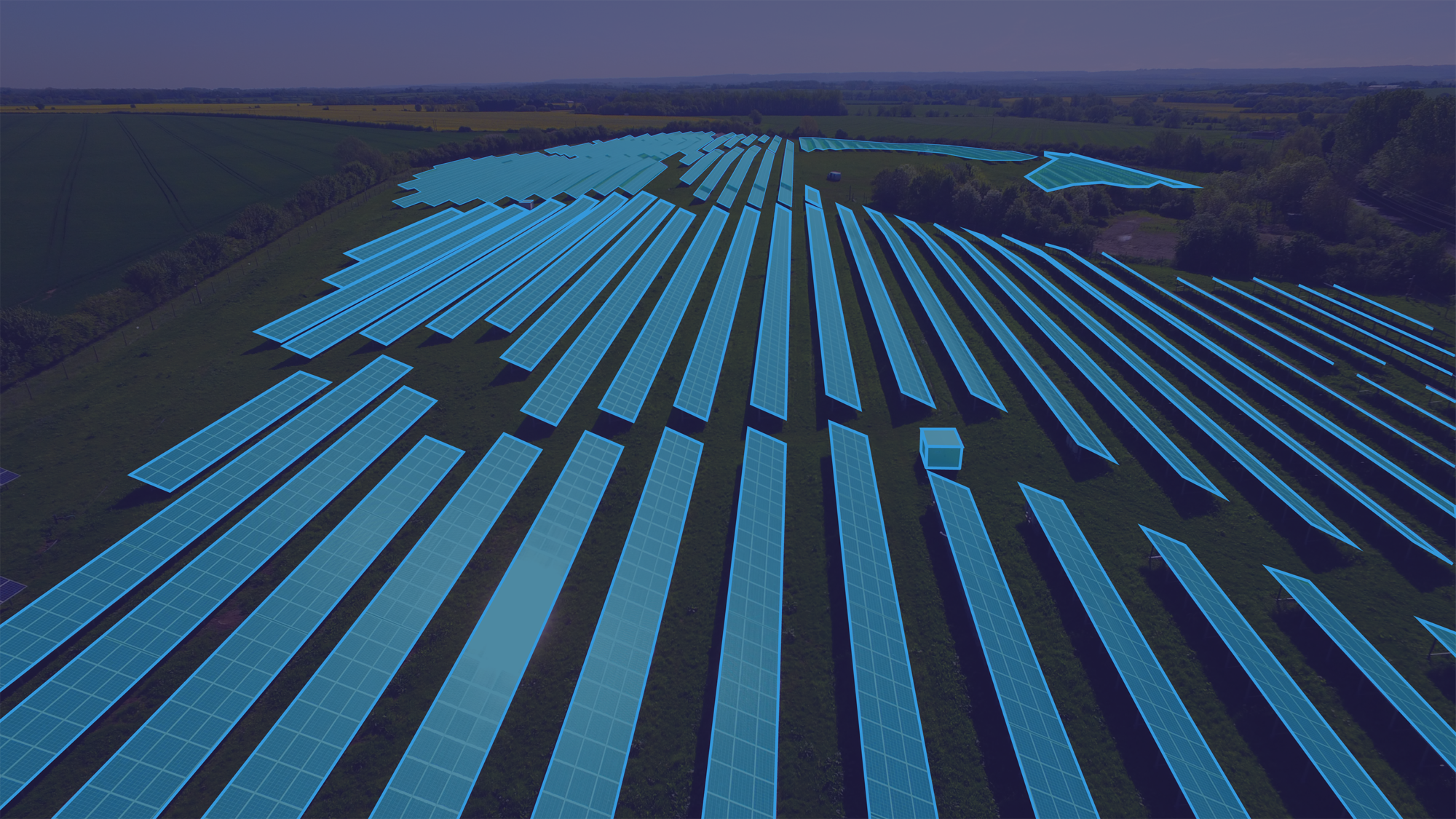

Increasingly large solar installations present unprecedented operational challenges. As a result, traditional practices and tools are no longer sufficient for managing utility-sized plants. In addition, the life expectancy of solar assets can now reach 40+ years. As plants age, issues with component quality, warranties and obsolescence are starting to appear and require further investment.

Why is technical debt a problem?

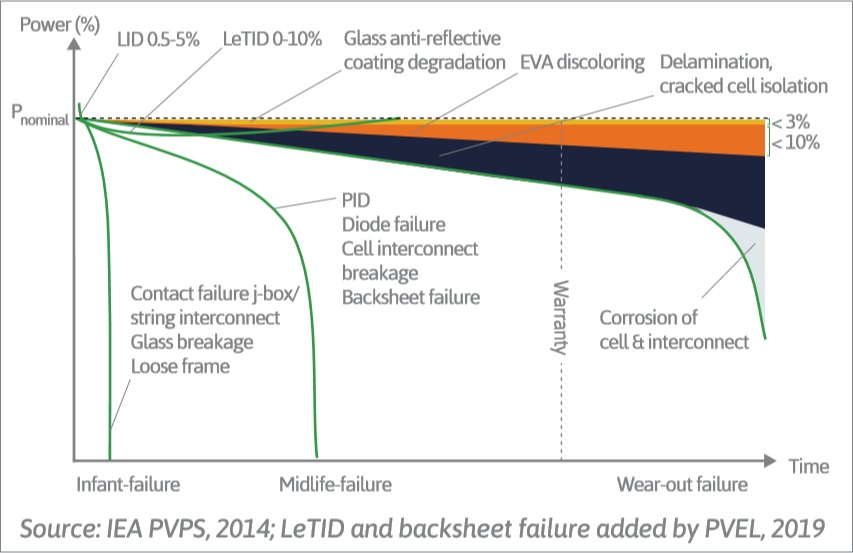

With older installations, technical debt was created in the “build now, fix problems later” frenzy driven by subsidies. In the rush to commission plants in time for specific subsidy deadlines, some decisions on quality may have been rushed. The challenges persist even in today’s post-subsidy times, where tight budgets could influence the choice of cost-effective, but potentially less optimal, equipment or design. Consequently, degradation, poor performance, failure, and even safety risks can materialise years after commissioning.

Common failure mechanisms experienced by solar panels

As a result of false economies, any short-term gains may be at the expense of long-term operational efficiency. Projects are often built around CapEx (Capital Expenditure), with little consideration to OpEx (Operational Expenditure).

In the context of solar PV projects, CapEx and OpEx are financial terms used to categorise different types of expenses related to the project’s development, operation, and maintenance. CapEx refers to the upfront capital investments required to acquire, design, and construct the solar PV system. OpEx refers to the ongoing operational expenses incurred to maintain and operate the solar PV system over its lifespan.

Despite the desire of many developers to prioritize their asset’s future operational maintenance, the rapidly growing industry leaves them little time for procedural changes.

How digital tools can support – Strategic digitisation from development

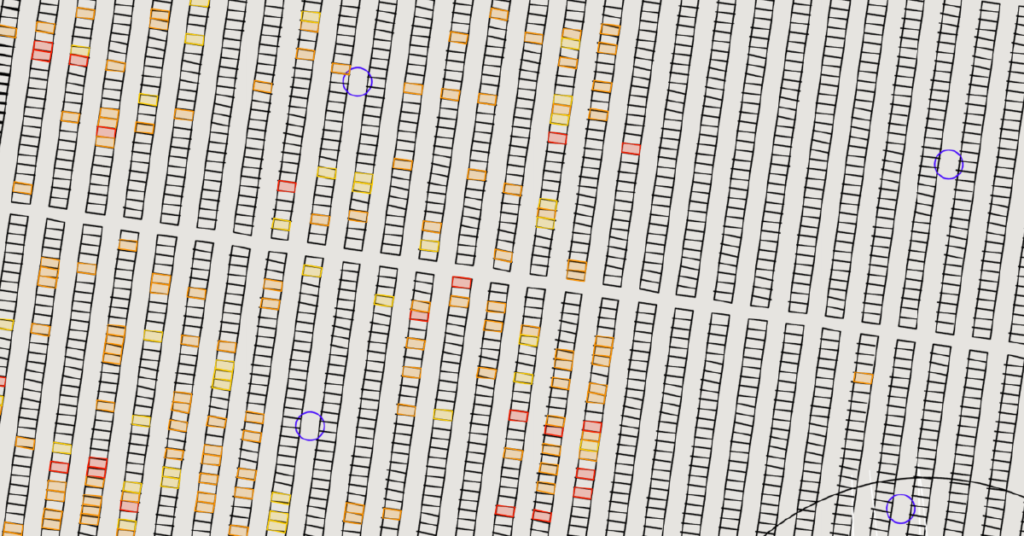

Thankfully the solar industry can learn from the software industry’s mistakes. By identifying and mapping the “known unknowns” from the outset, technical debt can be reduced or avoided. The term ‘known unknowns’ refer to the factors or information that are recognised as potential uncertainties or gaps in knowledge within a project. For example, a plant may consist of different batches of modules, perhaps from various manufacturers. Digitising their serial numbers and locations from the outset provides an overview of the module distribution across the entire asset. Subsequently, it will be easy to establish whether any problems affect all modules or just one batch. Collecting serial numbers and locations later, when the asset is already distressed and losing money, is time-consuming and expensive. Embracing digitisation not only helps prevent such expenses but also saves valuable time and human resources.

This commissioning Aerial Thermographic Report highlights module defects in one concentrated area, indicating potential issues with the batch’s quality. Identifying serial numbers, failure modes and locations aids in making a robust warranty claim with the manufacturer.

Streamlining Commissioning: Embracing Holistic Digital Plant Records for Seamless Data Management

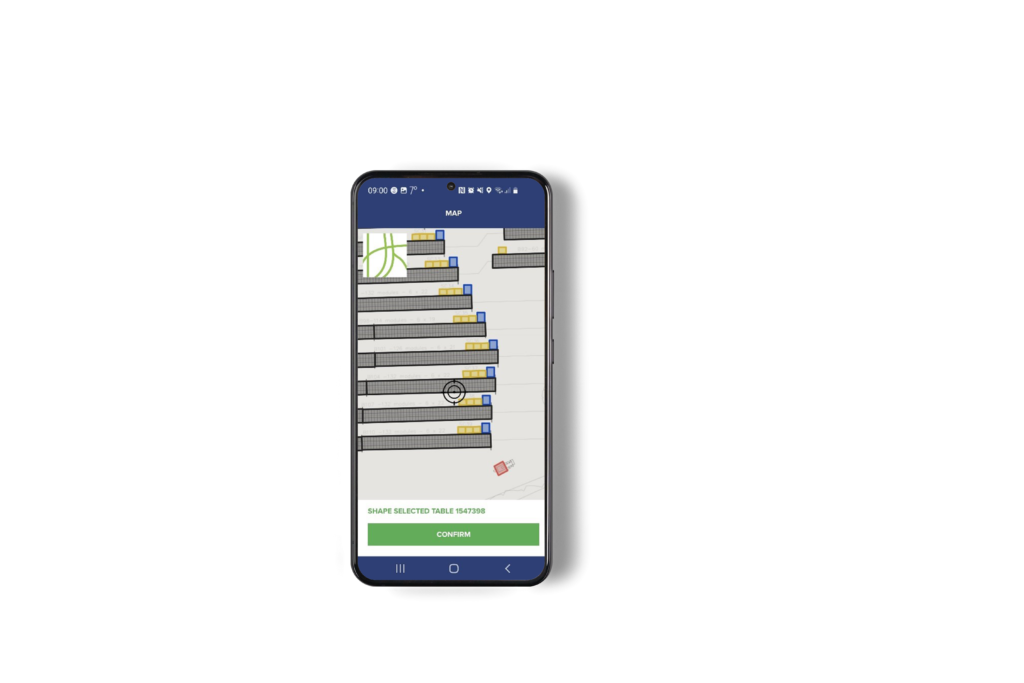

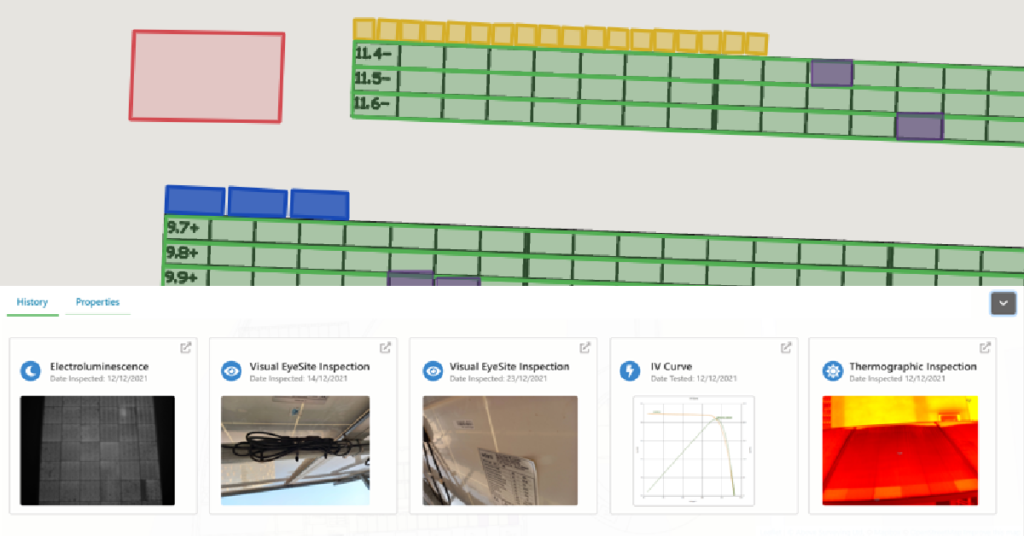

A huge number of observations, tests and measurements are carried at the commissioning stage, often by multiple parties. The information collected in this process is typically recorded in silos consisting of spreadsheets, Word documents and emails. As a result, it is often lost or forgotten during the handover from EPC to operation and maintenance. Creating holistic digital plant records from construction to commissioning can prevent this problem. These can be accessed on-site, via a mobile app that tells the user where exactly to find a specific module. The data can also be recorded into a digital twin, which holds all that baseline performance information.

What are the benefits of utilising holistic digital health records?

The operations and maintenance team can use this data to deal with any problems that may arise in the future. Furthermore, having a record of an existing plant provides

visibility into the asset’s health, history, and baseline. In addition, capturing site inspection and testing data in one place provides a robust dataset to demonstrate the asset’s value. Above all, this is an advantage for owners in case they want to sell the plant.

Reducing technical debt in solar is vital for efficient projects. Embracing digitisation and identifying known unknowns from the outset can save resources and prevent future issues. Holistic digital plant records streamline commissioning and maintenance, ensuring optimal performance and asset value. Prioritising long-term operational maintenance and cost optimisation are key for success in the evolving solar industry.