Are you wondering how to manage solar construction mistakes? With solar construction projects, meticulous planning and tracking are essential for success. Despite your best efforts mistakes can still occur, leading to delays and cost overruns. Straight away from the arrival of construction management software, identifying and recording these mistakes is much easier. Let’s explore some common solar construction deviations and how they can be spotted and recorded using innovative technology.

Navigating solar construction mistakes with module mounting

Issue: Installing solar modules at incorrect locations and angles to the design, carries a risk of row shading and underperformance.

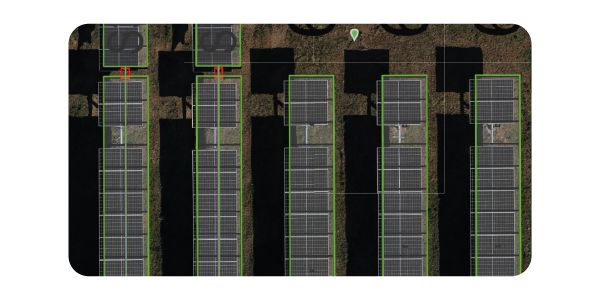

Tracking and Recording: Drone-based aerial imagery provides a detailed view of module placement on site. Overlaying digital construction drawings onto these images allows deviations from the design to be easily identified and recorded. Furthermore, using software, project managers can automatically generate a list of issues and share it with site teams via mobile to assess further. Mobile apps can record issues on the ground that are not visible with a drone, for example, variable structural tilts. Module mounting issues not recorded accurately and resolved can lead to mismatch losses and reduce yield.

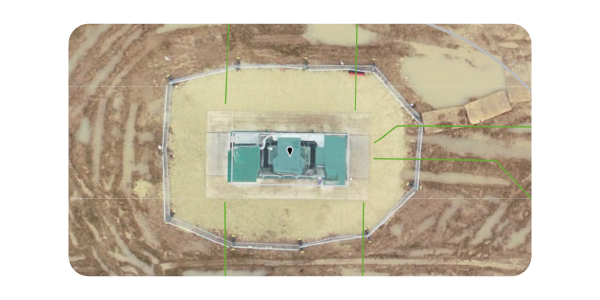

Identifying structural solar construction mistakes

Issue: Constructing structural components, such as module mounting systems incorrectly poses a huge risk to the future integrity of the solar plant.

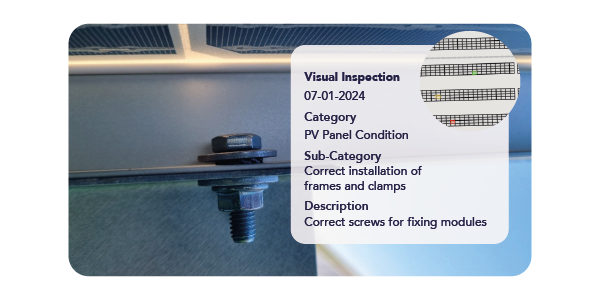

Tracking and Recording: Comparing designs with the construction site imagery enables the early detection of solar construction going off course during critical activities such as piling and racking installation. Drones have limitations with finer details, such as clamps, but mobile tools offer close-up image capture with annotations for detailed records and proof of correct installations. Solar Builder Mag sets out 10 structural solar mounting problems to avoid, as observed by PV Diagnostics

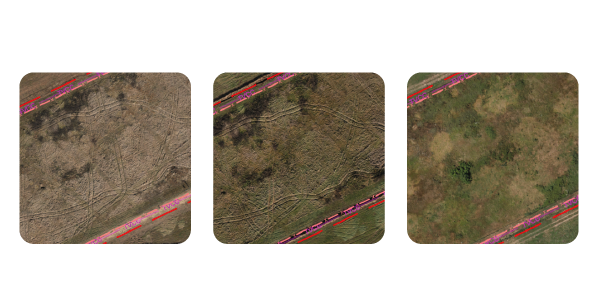

Spotting solar construction mistakes relating to cable runs

Issue: When cables are not properly routed or protected, they lead to failure and safety hazards. Equally, cable runs excavated in the wrong direction can increase unnecessary expenditure.

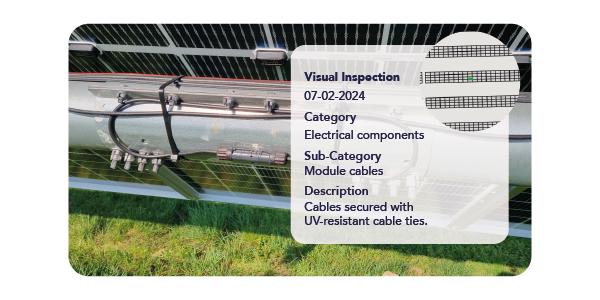

Tracking and Recording: If a cable route doesn’t go to plan it is often necessary to dig it back up. Drone imagery covers the entire site, aiding in spotting mismatches between cable installation and design. Digital construction management software allows you to turn layers on and off, allowing you to focus on specific infrastructure progress. Updating as-built drawings with the updated position resolves discrepancies, this can be informed by annotations and raising deviations effectively as a punch list. It is beneficial to get cable runs accurate as it prevents wasteful expenses and safety risks.

Managing the correct installation of components

Issue: Poorly installed smaller components, such as wiring connectors, can dramatically compromise the longevity and performance of the solar system.

Tracking and Recording: On-site teams should record their work to ensure high standards are met, best done with a mobile app for efficiency. For instance, electrical engineers should document work such as internal combiner box wiring and module cable fittings. Project managers can use software to evaluate the quality of work and address deviations from specified standards. Mobile tools automate data processing and facilitate quick remediation efforts for maintaining construction quality. If you’ve not experienced using a mobile app for solar you might want to read up on how to utilise mobile technology for solar, from development to operations.

Monitoring the environmental impact of construction work

Issue: Construction activities have resulted in environmental violations, such as soil erosion or habitat disruption.

Tracking and Recording: Tracking landscape changes and environmental impacts from construction activities is sometimes overlooked with everything going on. Drone-based aerial imagery provides the high-level overview managers need to stay informed on site conditions and meet commitments. Construction management software tools significantly help managers monitor compliance, measure habitat growth and record violations. Protected wildlife areas require regular monitoring, and documentation of conservation efforts like bird and bat boxes, which is easier to track over time using digital technology.

Staying aware of on-site ground conditions

Issue: Solar construction sites can be muddy places, and heavy rains present flood risks on-site which delay work. Solar construction site machinery easily churns up the ground, making it difficult to move materials around.

Tracking and Recording: Using aerial imagery, project managers can monitor the condition of access routes, making decisions on where to direct resources and materials. Aerial imagery of groundwater on site has the power to reveal problem areas missed in surveys. Unchecked groundwater poses a serious risk to electrical equipment and components susceptible to corrosion. Digital tools help measure and annotate issues, facilitating communication with on-site teams to respond by installing extra drainage channels for example.

Preparing for theft and damages

Issue: Theft of valuable components and damage from extreme weather.

Tracking and Recording: Theft is a high risk for solar managers, with precious metals, components, and machinery held on-site. Regular aerial inspections of the site can help managers identify vulnerable areas such as gaps in fencing. Another purpose in the event of theft is to evidence that the correct protective procedures were met for insurance providers.

Extreme weather is on the rise from heavy rain to high winds. Weather can damage a solar PV plant more than usual during construction because of loose materials and components not being fully installed. For this reason, digital management tools are useful to see the construction status before the incident and provide evidence for any warranty/insurance claims. We covered the topic of extreme weather damage and how to document it in this blog post.

Above all, digital monitoring through construction management software provides a robust solution for identifying and documenting solar construction mistakes and successes. Additionally, using this method project managers can address issues quickly and evidence the construction quality of completed solar projects. Speaking of completion, it is a must to get an IEC-compliant aerial thermographic inspection of the entire solar plant to spot any module defects. Unsure what an IEC-compliant thermal inspection is? Read our post on understanding IEC aerial thermography and why to use it. Embracing innovative technology is key to minimising risk and maximising the efficiency and quality of solar construction.

If you are interested in getting a demo from a member of our team you can request a demo here.