Identifying and understanding solar panel thermal anomalies

Want to understand solar plant thermal anomalies better? Understanding thermal solar plant reports is crucial. Let’s explore the different types and their common underlying causes.

Aerial thermographic inspection performed with drones has been around in the solar industry since 2015. Both data collection and data analysis have evolved a lot in the last eight years. So much so that aerial thermographic inspection has become a standard inspection, featured as best practice by solar industry associations such as Solar Power Europe. If you are new to aerial thermography check out our introduction to the topic for a concise overview.

Understanding the standard solar panel thermal anomalies

Heated Module Anomalies

A heated module anomaly is a module displaying unusual heating across its entire surface. This may have its origin within the module itself or could be a result of an external component issue.

Individual module heating can be caused by damage to the panel or issues such as open circuits. In most cases further investigation is needed to determine the exact root cause, however, some further insights can be obtained with the thermal and RGB imagery in thermal reports. Examples of this are shading, visual module surface damage and string heating.

One common cause of multiple heated modules is known as ‘string heating,’ where all modules within an electrical string are impacted due to a problem at the string level. Inverter-related issues can also cause widespread module heating.

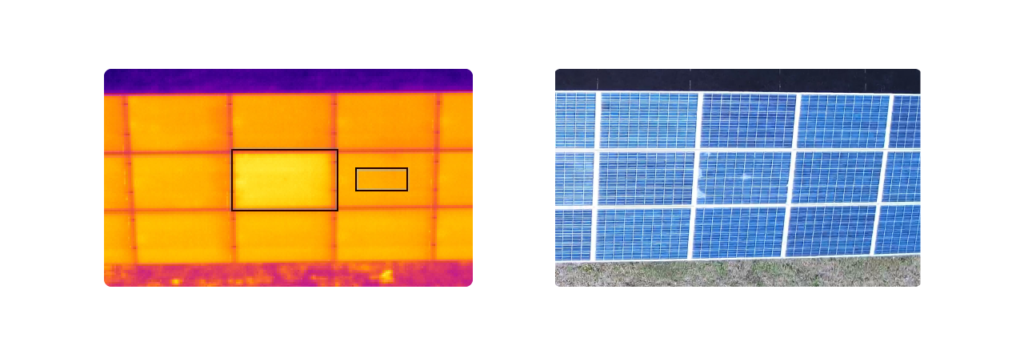

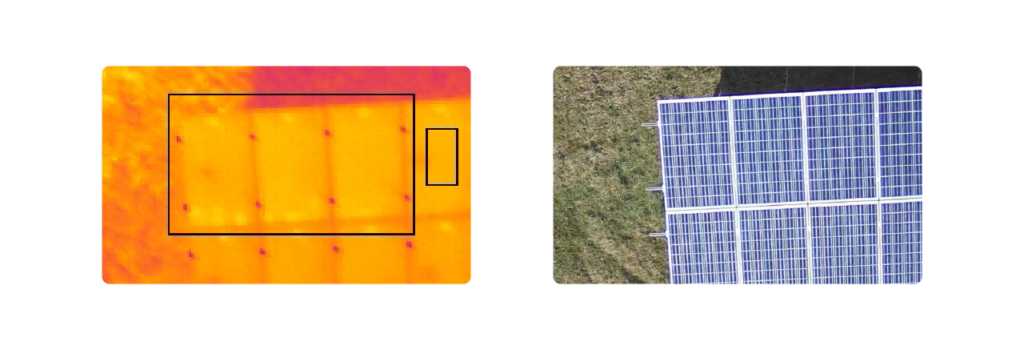

An image of a solar panel thermal anomaly called ‘Heated Module’, is shown via the brighter panel colour. The RGB image shows some damage or defect on the module surface

Solar panel thermal anomaly heated module type

Heated Substring Observations

Partial module heating—could it be diode-related or caused by external factors? Internally, the cells of a PV module are usually connected in series, forming chains of connected cells, called substrings. Typically, a PV module contains three substrings, each comprising either 20 or 24 cells, depending on the module type. These substrings are bridged by three bypass diodes that protect the cells from becoming a load for the whole module when the module is partially shaded, or a cell is degraded or broken.

When these substrings are bypassed, they become cut off, ceasing energy production. Consequently, they exhibit higher temperatures compared to normally functioning cells within the same PV module.

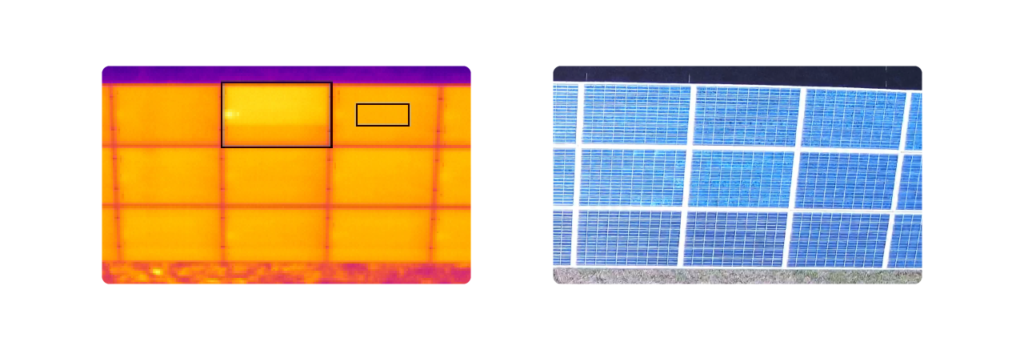

Heated substring thermal anomalies can cover one or two-thirds of the module (or other proportions, in newer module types e.g. half-cut modules). A few examples of what can cause a heated sub-string are diode activation and malfunction, lightning strikes and loose connections which can lead to localised heating.

Solar thermal sub-string anomaly type

Hot Spots and Multiple Hot Cells

A hot spot is an easy one to spot, most of the time. It is simply a single heated cell. Hot spots can indicate various underlying issues, such as soiling, shading and module damage.

Multiple hot spots are you guessed it, more than one hot cell on the module. RGB visual imagery is useful for spotting soiling and shading as probable root causes that can be seen on the module surface. Soiling and shading are usually resolved by having the plant cleaned and overgrown plants trimmed. A shaded cell, whether by a tree or pole, acts as a resistor, driving away energy produced by other cells in the string. In some cases, the shading is permanent from the design of the solar plant components.

If soiling or shading is not the problem, further testing is needed to identify hidden causes such as cracks, delamination, cell shunting and cell mismatch. Thermal imaging should be followed up by more detailed ground-based inspections, for example, up-close visual inspections, RISO testing and EL can help paint a clearer picture of the problem.

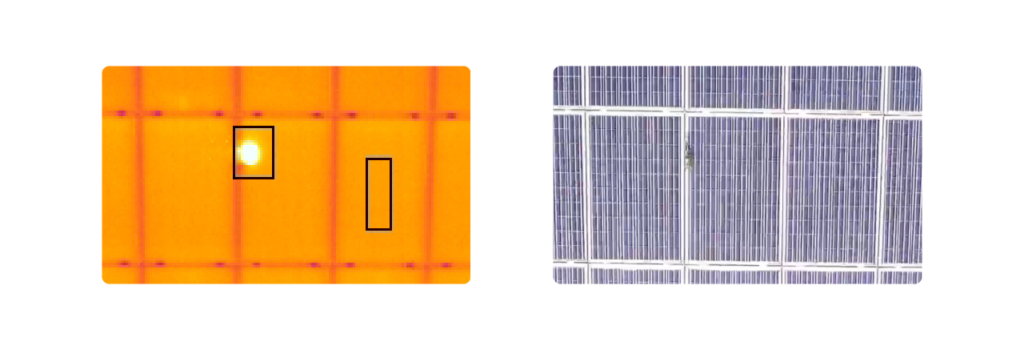

Solar panel thermal anomaly hot spot type with a probable root cause of arboreal shading, you can see a plant growing between the frame.

Heated Junction Box: Anomalies Beyond Modules

Heated junction box anomalies require more consideration to identify. This is because the junction box is supposed to be slightly warmer than the module itself. That being said unusual heat in junction boxes demands attention, we record a heated junction box when it is significantly hotter than the average of the site. The reason behind this raised temperature can be loose connections, corrosion, junction box fault or an activated diode. A faulty junction box has been known to completely melt due to electrical arching and can pose substantial risk.

“PVEL has reported junction box-related failure issues in every edition of its module Scorecard since 2019. This problem remains persistent both in the failures identified by PQP testing and on modules in the field.” – PVEL 2023

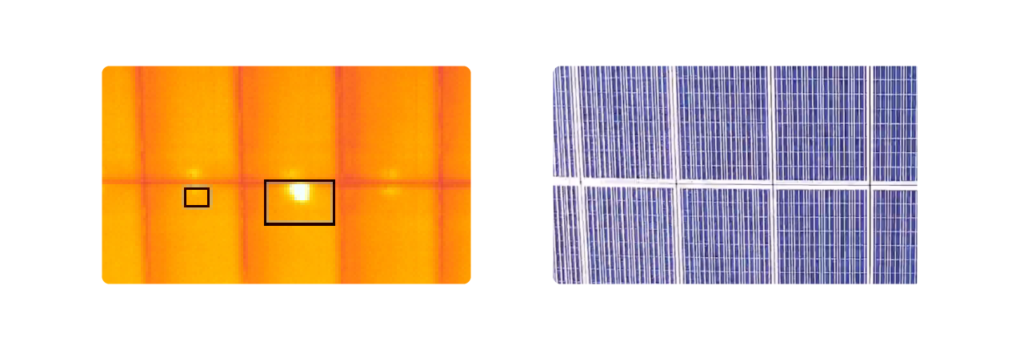

Solar panel thermal anomaly heated junction box type. You can see the other normal temperature junction boxes on other panels, the highlighted junction box is much hotter.

SEHP: A Telltale Sign of Potential Induced Degradation (PID)

A string-end heating pattern(SEHP) occurs as a repeated pattern across the site or in large areas, ‘SEHP’ is our term for a pattern of heating that might indicate the onset of PID. Affected cells are usually located at the negative end of a string.

When this pattern is identified it is highly likely to be PID but that’s not always the case. PID is a systemic issue on solar modules that progresses slowly. PID can cause irreversible damage to solar plants, in many cases it can be reversed so the earlier you identify it, the more success you will have in recovering the situation.

Solar panel thermal anomaly string end heating pattern (SEHP) type. This anomaly pattern is often displayed when PID is present.

Additional solar panel thermal anomalies: Beyond Module Heat

Thermal inspections can also identify non-thermal issues such as missing modules and tracker faults. Often these observations are due to maintenance activities, however, missing modules can be observed after extreme weather, and examples such as high winds can remove modules. Tracker alignment and mechanism faults that impact panel orientation can decrease performance significantly, on huge solar plants it can be difficult to notice issues when on site.

Solar module thermal anomaly tracker type. This example shows a tracker misalignment issue which could affect production especially if a large area is misaligned.

In this comprehensive guide, we’ve covered diverse solar panel thermal anomalies, their visual cues, and their underlying causes. Identifying these issues early can optimise your plant’s efficiency and inform maintenance work.